The swing jaw is a core load-bearing component in jaw crushers that directly drives the swing jaw plate to perform reciprocating motion, functioning as the "movable jaw" of the equipment. Its upper end is connected to the eccentric shaft via bearings, and its lower end is linked to the frame through the toggle plate. Driven by the eccentric shaft, it swings back and forth periodically, pushing the swing jaw plate to cooperate with the fixed jaw plate to crush materials. The swing jaw must withstand both the impact load of materials and the torque transmitted by the eccentric shaft, thus requiring extremely high structural rigidity, material strength, and machining precision.

The structural design of the swing jaw balances force transmission efficiency and deformation resistance. Its core components and structural features are as follows:

Swing Jaw Body (Main Body)

It has an overall "L" or box-shaped structure, made of high-strength cast steel or forged steel, serving as the main frame of the swing jaw. Swing jaws of small and medium-sized crushers are mostly integrally cast, while large ones adopt welded or cast-welded structures (to reduce weight and enhance rigidity). Its front face (material-contacting side) is machined with a flat surface or T-slots for fixing the swing jaw plate via bolts or wedge blocks; the rear face is designed with a toggle plate seat (an arc-shaped groove connected to the toggle plate), whose curvature must precisely match the support end of the toggle plate to ensure uniform force distribution.

Bearing Seat (Upper Bearing Hole)

Located at the upper part of the swing jaw body, it is a key part connected to the eccentric shaft, with built-in rolling or sliding bearings. The bearing seat is usually cast integrally with the swing jaw body (large swing jaws use sleeved bearing seats for easy replacement). Its axis is perpendicular to the front face of the swing jaw body, and the internal machining accuracy must reach IT6 grade with a surface roughness of Ra ≤ 1.6 μm to ensure stable cooperation with the eccentric shaft.

Toggle Plate Seat (Lower Support Part)

Located at the lower part of the swing jaw body, it is an arc-shaped groove structure for installing one end of the toggle plate. The groove is usually inlaid with a wear-resistant liner (e.g., ZGMn13) to reduce wear during the toggle plate's swing. The radius of curvature of the toggle plate seat must match the toggle plate, with a gap controlled between 0.1-0.3 mm to avoid abnormal noise or impact during operation.

Reinforcing Ribs

Crisscross reinforcing ribs are distributed inside or outside the swing jaw body, especially in stress concentration areas between the bearing seat and the toggle plate seat. The thickness of the ribs is usually 10-30 mm (adjusted according to the swing jaw size) to enhance overall bending resistance and deformation resistance.

Weight-Reduction Holes (Large Swing Jaws)

Circular or rectangular weight-reduction holes are designed in non-force-bearing areas of extra-large swing jaw bodies to reduce weight without reducing strength, thereby lowering the load on the eccentric shaft.

The swing jaw must withstand high-frequency impacts and heavy loads, so it is usually made of high-strength cast steel (e.g., ZG270-500, ZG35CrMo) or low-alloy forged steel. The casting process must ensure dense internal structure and freedom from defects. The specific process is as follows:

Mold Preparation

Resin sand casting (for small and medium swing jaws) or sodium silicate sand casting (for large swing jaws) is adopted. Wooden or foam patterns are made according to 3D drawings, accurately replicating the swing jaw body, reinforcing ribs, bearing seats, etc., with a 6-10 mm machining allowance reserved (cast steel has a shrinkage rate of about 1.5%).

The cavity surface must be smooth, and key parts such as the bearing seat and toggle plate seat require precision forming to avoid excessive dimensional deviation after casting. Multiple risers are set (especially in thick parts of the bearing seat) to ensure sufficient feeding of molten metal and reduce shrinkage cavities.

Melting and Pouring

Scrap steel and pig iron with low phosphorus (P ≤ 0.04%) and low sulfur (S ≤ 0.04%) are proportioned and melted in an electric arc furnace or medium-frequency furnace to 1520-1580°C. The chemical composition is controlled (e.g., ZG35CrMo: C 0.32-0.40%, Cr 0.8-1.1%, Mo 0.15-0.25%).

Deoxidation treatment (adding calcium-silicon alloy) is performed before pouring to ensure the purity of the molten steel. A stepped pouring system is used, with molten metal slowly filling the cavity from the bottom to avoid slag entrainment or porosity. The pouring time is controlled between 5-15 minutes depending on the weight of the swing jaw.

Shakeout and Heat Treatment

The casting is shakeout after cooling to below 300°C. Risers are removed (flame cutting for large swing jaws, mechanical cutting for small ones), and gate marks are ground smooth.

Normalizing + tempering treatment is carried out: heating to 880-920°C and holding for 2-4 hours (heating with the furnace to avoid cracking due to excessive temperature difference), followed by air cooling and tempering at 550-600°C to eliminate casting stress, resulting in a hardness of 180-230 HBW and impact energy ≥ 30 J.

The machining accuracy of the swing jaw directly affects the cooperation stability with the eccentric shaft and toggle plate, requiring multiple processes to ensure key dimensions and geometric tolerances:

Rough Machining

Using the upper and lower end faces of the swing jaw body as references, the front face (where the swing jaw plate is installed) and rear face (toggle plate seat area) are rough-milled on a CNC gantry milling machine or boring machine, leaving a 2-3 mm finishing allowance, with flatness error controlled at ≤ 0.5 mm/m.

Rough boring of the bearing seat hole: The upper bearing hole is machined on a horizontal boring machine, with a 3-5 mm grinding allowance reserved for the diameter, ensuring the perpendicularity of the hole axis to the front face is ≤ 0.1 mm/100 mm.

Semi-Finishing

Finish milling of the front and rear faces: The end mill is used to machine to the design size, with surface roughness Ra ≤ 6.3 μm, flatness ≤ 0.1 mm/m, and perpendicularity of the front face to the bearing seat hole axis ≤ 0.05 mm/100 mm.

Processing of the toggle plate seat: A special forming milling cutter is used to mill the arc groove, ensuring the curvature radius deviation ≤ 0.1 mm, the groove surface roughness Ra ≤ 12.5 μm, and inlaying a wear-resistant liner (fixed by bolts, with a gap between the liner and groove ≤ 0.1 mm).

Finishing

Precision boring and grinding of the bearing seat hole: A precision boring machine or internal grinder is used for processing, ensuring the hole diameter tolerance is IT6, surface roughness Ra ≤ 0.8 μm, roundness ≤ 0.005 mm, and axis straightness ≤ 0.01 mm/m.

Drilling and tapping: Bolt holes (or T-slots) for fixing the swing jaw plate are machined on the front face, with hole position tolerance ± 0.2 mm and thread accuracy 6H; lubrication holes are drilled near the toggle plate seat to ensure smooth oil passages.

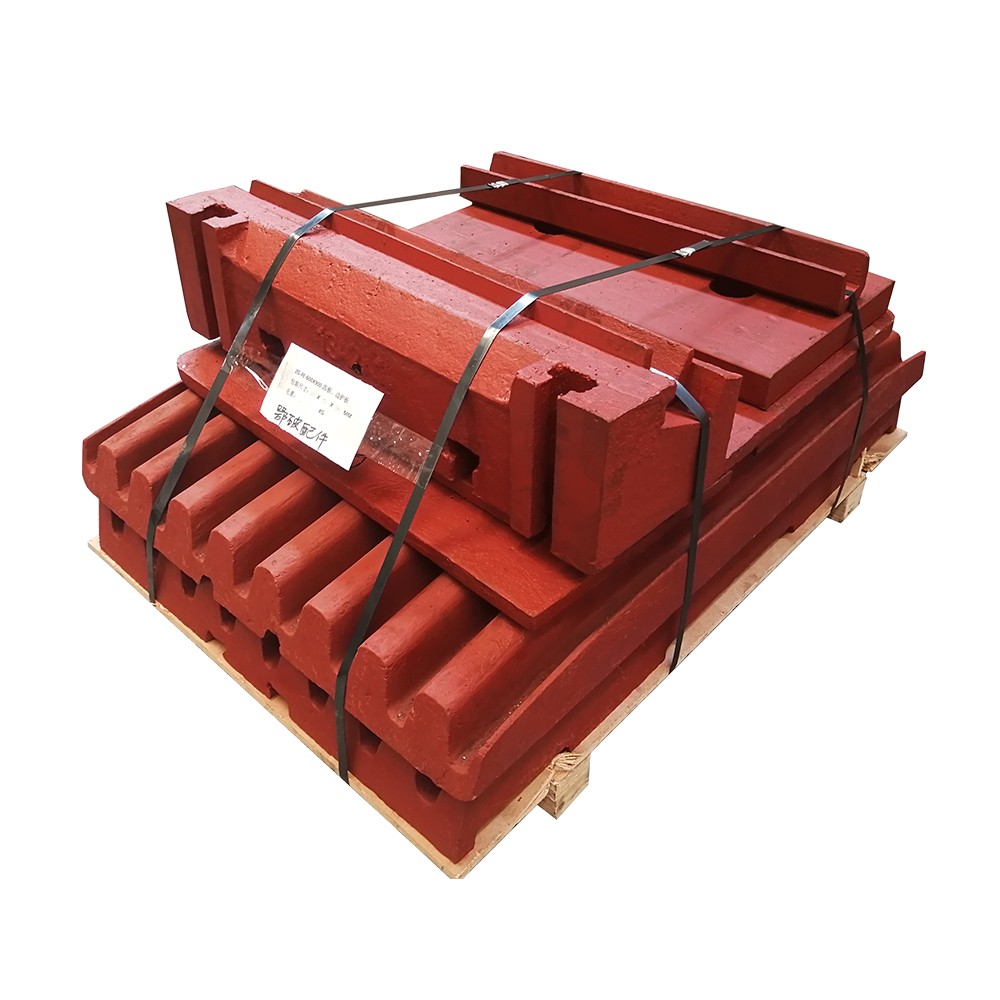

Assembly Surface Treatment

All machining burrs are removed. The bearing seat hole is phosphated (to enhance cooperation stability with the bearing), and non-machined surfaces are painted for rust prevention (primer + topcoat, film thickness 60-80 μm) to ensure no missing coating or sagging.

As a core load-bearing component, the quality control of the swing jaw covers key indicators such as material, machining accuracy, and structural strength:

Material and Casting Quality Control

Chemical composition inspection: A spectrometer is used to analyze the content of C, Cr, Mo, etc., ensuring compliance with cast steel standards (e.g., Cr content of ZG35CrMo is 0.8-1.1%).

Internal defect detection: 100% ultrasonic testing (UT) is performed on key parts such as the bearing seat and reinforcing ribs, prohibiting pores or inclusions with an equivalent size ≥ φ3 mm; magnetic particle testing (MT) is used for surface inspection, prohibiting cracks or folding defects.

Machining Accuracy Inspection

Dimensional tolerance: Calipers and micrometers are used to detect the flatness of the front face and the diameter of the bearing seat hole, with deviations within the allowable range of the drawings; a coordinate measuring machine is used to detect the positional accuracy of the bearing seat hole and toggle plate seat, ensuring the axis parallelism ≤ 0.1 mm/m.

Geometric tolerance: A laser interferometer is used to measure the straightness of the bearing seat hole, and a dial indicator is used to check the parallelism between the front face and rear face (error ≤ 0.1 mm/m).

Mechanical Performance Verification

Sampling for tensile testing (tensile strength ≥ 500 MPa, yield strength ≥ 270 MPa) and impact testing (-20°C impact energy ≥ 27 J) to ensure the material toughness meets the standards.

Static load strength testing: 1.2 times the rated load is applied under simulated working conditions for 1 hour, detecting whether the swing jaw body is deformed (deflection ≤ 0.2 mm/m) or cracked.

Assembly and Test Run Inspection

Trial assembly with the eccentric shaft and toggle plate is conducted to check the cooperation gap between the bearing seat and the eccentric shaft (complying with H7/js6 tolerance) and the fitting degree between the toggle plate and the toggle plate seat (contact area ≥ 80%).

Commissioning test: Running at the rated speed on the crusher for 2 hours, monitoring whether the swing jaw swings stably without abnormal vibration (amplitude ≤ 0.1 mm) or noise.

Through strict casting, machining, and quality control, the swing jaw can maintain structural stability under long-term high loads, with a service life of 5-10 years (depending on material hardness and maintenance frequency). In actual use, it is necessary to regularly check the wear of the bearing seat and whether there are cracks in the reinforcing ribs, and perform timely maintenance to avoid sudden failures