Detailed Introduction to Mobile Cone Crusher

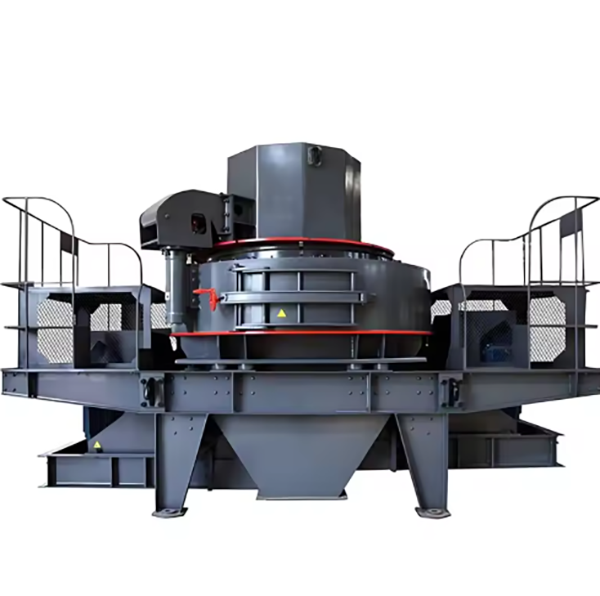

1. Overview and Application of Mobile Cone Crusher

Mobile cone crusher is a integrated crushing equipment that combines a cone crusher, feeding device, screening device, conveyor belt, and mobile chassis. It is designed for on-site crushing of medium to hard materials, such as granite, basalt, iron ore, and concrete aggregates. Its biggest advantage is mobility, which allows it to move flexibly between construction sites, reducing material transportation costs and improving crushing efficiency.

This equipment is widely used in mining, road construction, urban demolition, and infrastructure projects. It can perform secondary or tertiary crushing, producing aggregates with uniform particle size and high cubicity, which can be directly used in construction or further processed. The processing capacity of mobile cone crushers ranges from 50 to 500 tons per hour, meeting the needs of different scales of projects.

2. Composition and Structure of Mobile Cone Crusher

Mobile cone crusher is a complex system composed of multiple components, each with a specific function to ensure the smooth progress of the crushing process:

2.1 Mobile Chassis

2.2 Cone Crusher Unit

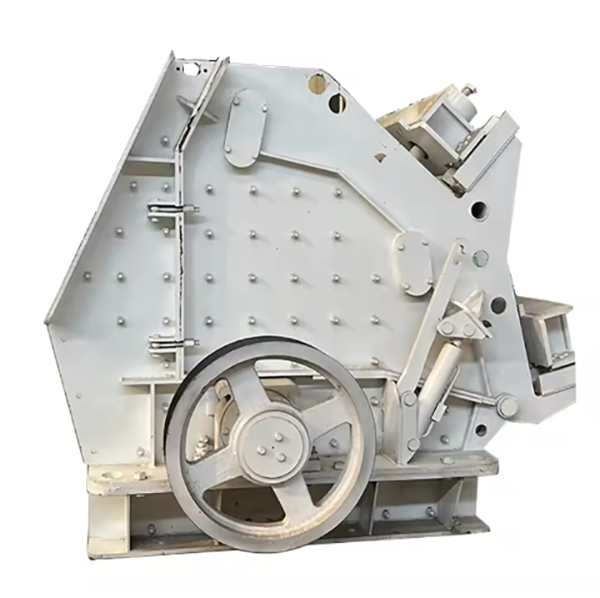

Crushing Chamber: Consists of a fixed cone (concave) and a moving cone, both lined with wear-resistant liners (high-chromium cast iron Cr20). The fixed cone is installed on the frame, and the moving cone is driven by an eccentric shaft to perform periodic swing, crushing materials through extrusion and impact.

2.3 Feeding and Screening System

Vibrating Screen: A circular or linear vibrating screen installed at the discharge end of the cone crusher. It screens the crushed materials into different particle sizes (e.g., 0–5 mm, 5–10 mm, 10–20 mm). The screen mesh is made of high manganese steel (ZGMn13) or polyurethane.

2.4 Conveyor System

Main Conveyor: Transports the crushed materials from the cone crusher to the vibrating screen. It is composed of a conveyor belt (rubber material, thickness 5–10 mm), rollers, and a driving device.

2.5 Hydraulic and Electrical Systems

Hydraulic System: Includes hydraulic pumps, cylinders, and control valves. It is used for adjusting the discharge port of the cone crusher, lifting the feeding hopper, and controlling the movement of the crawler tracks (for crawler-type mobile crushers). The working pressure is 16–25 MPa.

Electrical Control System: A PLC control cabinet with a touch screen, which can realize automatic control of the equipment, such as starting and stopping in sequence, overload protection, and fault alarm. It is also equipped with a remote control device for convenient operation.

3. Manufacturing Processes of Mobile Cone Crusher

3.1 Mobile Chassis Frame (Q355B Steel)

Welding: The frame components are welded using submerged arc welding, with a weld seam height of 8–15 mm. After welding, the frame is subjected to stress relief annealing at 600–650°C to eliminate welding stress.

Machining: The mounting surfaces for the cone crusher, motor, and hydraulic system are machined using a CNC milling machine, ensuring flatness ≤0.1 mm/m and surface roughness Ra3.2 μm.

3.2 Cone Crusher Components

3.3 Vibrating Screen (High Manganese Steel ZGMn13)

Screen Frame: Welded using Q355B steel, then stress-relieved. The screen surface is made of high manganese steel plates, which are cut and punched to form the screen mesh with a hole size tolerance of ±0.5 mm.

4. Processing Processes

4.1 Cone Crusher Assembly

4.2 Mobile Chassis Assembly

4.3 Electrical System Wiring

Wire Routing: The electrical wires are laid in cable trays, with proper insulation and protection. The connections between the motor, control cabinet, and sensors are made using terminal blocks, ensuring reliable contact.

Programming: The PLC control system is programmed according to the operation logic, including start-up sequence, overload protection parameters, and fault handling procedures.

5. Quality Control Processes

The frame, cone crusher components, and conveyor belts are inspected using calipers, micrometers, and CMM (Coordinate Measuring Machine) to ensure dimensional accuracy.

No-load Test: The equipment is run without load for 2 hours to check the rotation of the cone crusher, vibrating screen, and conveyors, ensuring no abnormal noise or overheating (bearing temperature ≤70°C).

Load Test: The equipment is tested with materials (e.g., granite) for 8 hours, checking the processing capacity, product particle size distribution, and stability of the hydraulic and electrical systems.

Mobility Test: For tire-type mobile crushers, road tests are conducted to check the driving performance and braking system. For crawler-type, tests on rough terrain are performed to verify the climbing ability and stability.

6. Installation Process

Mobile cone crusher, with its flexible mobility and efficient crushing performance, has become an important equipment in modern engineering construction. Through strict manufacturing processes, precise processing, and comprehensive quality control, it can meet the harsh working conditions of various construction sites and provide high-quality aggregates for projects