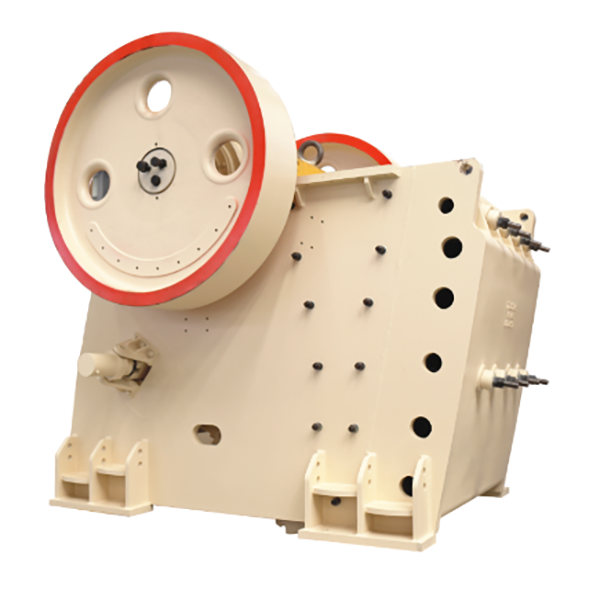

Double toggle Jaw Crusher

The double pendulum jaw crusher, characterized by its compact structure and the elliptical trajectory of the moving jaw (combining extrusion and grinding), offers 15–30% higher efficiency than the simple pendulum type, suitable for medium-hard materials (e.g., granite, iron ore) with a crushing ratio enabling output sizes of 10–300 mm.

Its core components include a frame (cast or welded), fixed/moving jaws (with high-chromium or ZGMn13 liners), an eccentric shaft (40Cr/42CrMo forged), a toggle plate (safety component), and hydraulic adjustment systems. Manufacturing involves precision forging (eccentric shaft forging ratio ≥3), water toughening of liners, and strict quality control—raw material UT inspection, bearing fit clearance (0.1–0.2 mm), and 4-hour load testing (≥90% particle size compliance).

Widely used as secondary or primary crushing equipment in mining (metal/non-metal ores), construction materials (recycled aggregates), and infrastructure (road base materials), it excels in small-to-medium production lines (10–200 t/h) requiring efficient medium-fine crushing.

More