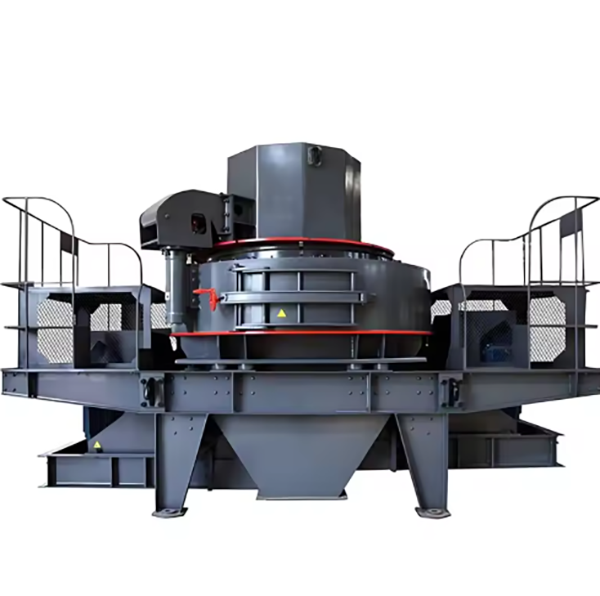

Detailed Introduction to Vertical Mill

1. Overview and Application of Vertical Mill

Vertical mill is a high-efficiency grinding equipment integrating crushing, drying, grinding, and classification. It works on the principle of material being crushed and ground between a rotating grinding disc and grinding rollers. The motor drives the grinding disc to rotate, and materials are fed into the center of the disc, then moved to the edge by centrifugal force. Under the pressure of the grinding rollers, materials are crushed and ground into powder, which is then carried by hot air to the classifier. Fine particles that meet the fineness requirement are collected as products, while coarse particles fall back to the grinding disc for re-grinding.

This equipment is widely used in cement, metallurgy, mining, electric power, and chemical industries, suitable for grinding various materials such as limestone, coal, slag, and ore. It features high grinding efficiency (30–50% higher than ball mills), low energy consumption, and adjustable product fineness (80–400 mesh), making it an ideal choice for large-scale powder production.

2. Composition and Structure of Vertical Mill

Vertical mill consists of several key systems working in coordination to achieve efficient grinding:

2.1 Main Body Structure

Grinding Rollers: 2–4 rollers (depending on the model) made of high-chromium cast iron (Cr20–25) or alloy steel, with a diameter of 0.5–2 m. They are installed above the grinding disc, pressing materials under hydraulic pressure (10–30 MPa) to realize grinding.

2.2 Feeding and Drying System

2.3 Classification System

Classifier: A dynamic rotor classifier installed at the top of the mill, consisting of a rotating impeller and a stationary guide vane. It separates fine and coarse particles by centrifugal force: fine particles pass through the impeller gap, while coarse particles are thrown back. The classifier speed (1000–3000 rpm) is adjustable to control product fineness.

2.4 Hydraulic System

2.5 Drive System

2.6 Powder Collection System

3. Manufacturing Processes of Vertical Mill

3.1 Grinding Disc (ZG35CrMo Cast Steel)

3.2 Grinding Rollers (High-Chromium Cast Iron Cr20–25)

3.3 Main Shaft (42CrMo Forging)

4. Processing Processes

4.1 Grinding Disc Machining

4.2 Grinding Roller Machining

4.3 Main Shaft Machining

4.4 Frame Machining

Milling: CNC milling machines process mounting surfaces for the main shaft, grinding rollers, and classifier, ensuring flatness ≤0.15 mm/m.

5. Quality Control Processes

6. Installation Process

Vertical mill, through advanced manufacturing and strict quality control, delivers efficient and reliable powder grinding, playing a key role in industrial production lines requiring high-performance grinding equipment