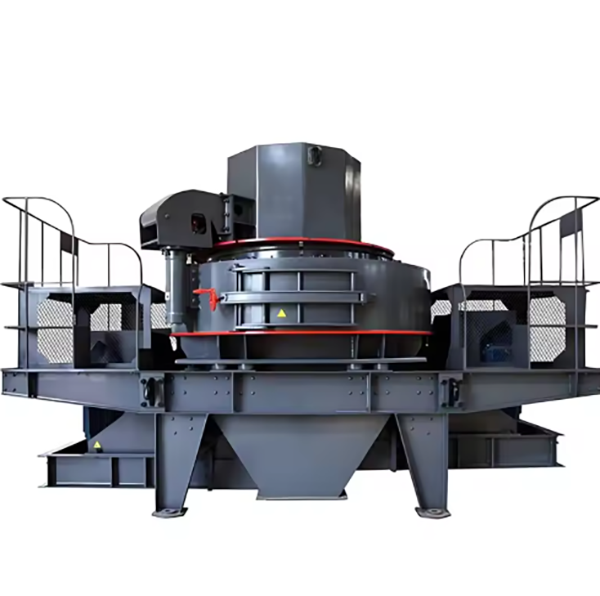

Detailed Introduction to VSI Sand Making Crusher

1. Overview and Application of VSI Sand Making Crusher

VSI (Vertical Shaft Impact) sand making crusher is a high-efficiency equipment designed for producing high-quality artificial sand and shaping aggregates. It utilizes the principle of "stone-on-stone" or "stone-on-iron" impact crushing: materials are accelerated by a high-speed rotating rotor (speed 2800–3500 rpm) and thrown against the crushing chamber liner or other materials, achieving crushing through impact, friction, and shearing.

This crusher is widely used in construction, highway, railway, and water conservancy projects, suitable for processing materials such as granite, limestone, river pebbles, and ore. It produces sand with excellent grain shape (high cubicity, low needle-like content ≤10%) and adjustable fineness modulus (2.6–3.0), meeting national standards for construction sand.

2. Composition and Structure of VSI Sand Making Crusher

VSI sand making crusher consists of core components working in coordination to ensure efficient sand production:

2.1 Main Body Assembly

2.2 Rotor Assembly

2.3 Feeding and Distribution System

Material Distributor: A cone-shaped component inside the upper cover, distributing materials into two parts: one part enters the rotor for acceleration, and the other falls into the crushing chamber for "stone-on-stone" crushing.

2.4 Drive System

Pulley/Coupling: For V-belt drive, a large pulley on the main shaft and a small pulley on the motor ensure a transmission ratio of 1:1.2–1:1.5. Couplings (e.g., elastic pin coupling) are used for direct drive to reduce energy loss.

2.5 Lubrication and Cooling System

3. Manufacturing Processes of VSI Sand Making Crusher

3.1 Rotor Disk (42CrMo Forging)

3.2 Throwing Heads (High-Chromium Cast Iron Cr20–25)

3.3 Main Shaft (40CrNiMoA Forging)

4. Processing Processes

4.1 Rotor Disk Machining

Rough Machining: CNC milling machine processes the outer circle, end face, and mounting holes for throwing heads, leaving a 1–2 mm allowance.

4.2 Main Shaft Machining

Turning: CNC lathe processes the outer circle, steps, and keyways, leaving a 0.3–0.5 mm grinding allowance.

4.3 Crushing Chamber Liner (High-Chromium Cast Iron)

4.4 Frame and Cover Machining

5. Quality Control Processes

Test Run: Empty run for 2 hours to check bearing temperature (≤70°C) and noise (≤85 dB). Load test with river pebbles for 8 hours to verify sand production rate, grain shape, and wear of throwing heads.

6. Installation Process

Foundation Preparation: Concrete foundation (C30 grade) with embedded anchor bolts, levelness ≤0.1 mm/m, cured for 28 days. A vibration isolation pad (5–10 mm thick) is placed on the foundation to reduce noise and vibration transmission.

VSI sand making crusher, through precise manufacturing, strict quality control, and standardized installation, ensures efficient production of high-quality artificial sand, meeting the demands of modern construction projects