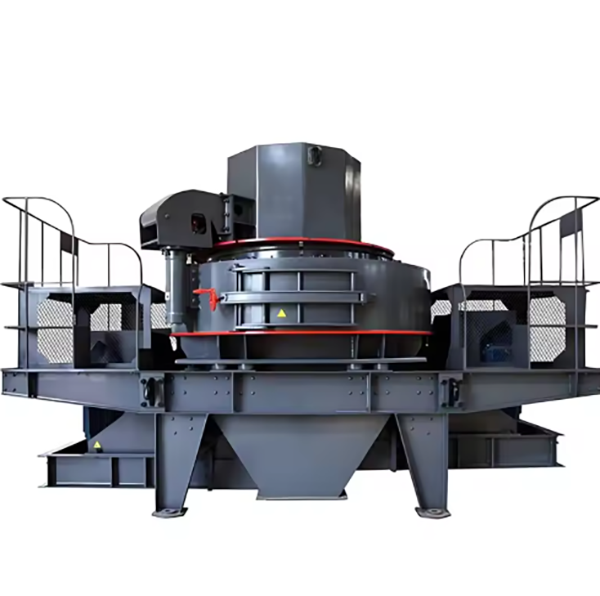

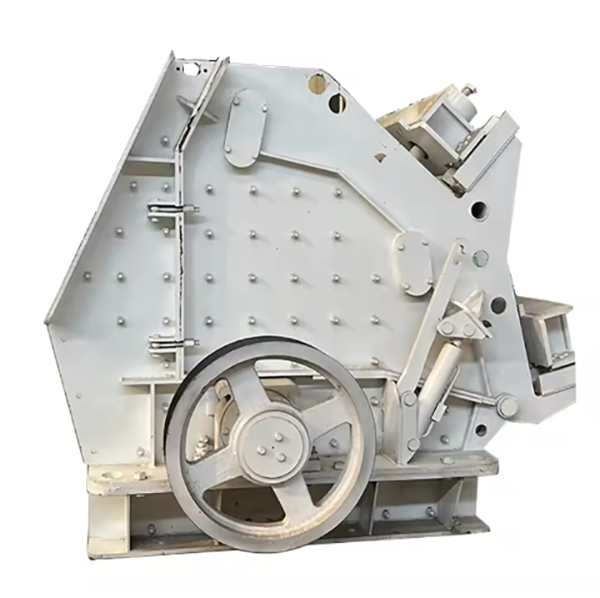

1. Compound cone crusher Product introduction

The compound cone crusher has a very wide range of uses, which can crush medium and above materials.There are four crushing cavity types for each model, such as coarse, medium, fine, and superfine. Using the best combination of crushing frequency and eccentricity, the material to be crushed is more finely crushed, and the crushing capacity has a higher output compared with similar models. At the same time, it also enhances the lamination and crushing effect between the material particles, effectively improving The three-dimensional shape of the crushed material. The equipment adopts optimized design through the use of hydraulic insurance, hydraulic locking, hydraulic adjustment, hydraulic cavity cleaning and other devices, the operation becomes easier to be automated. As normal, our equipment adopts optimized design and it makes the trouble-free operation rate exceed 95%.

2. Compound cone crusher Structural features

1. Higher Capacity of productivity, Higher quality.

2. the downtime is greatly reduced because of the safety device,

3. The machine body is a cast steel structure, with reinforcing ribs at the heavy-duty part.

4. With adjuster, it can quickly adjust the size of crushed material.

5. Provide spring type protection device.

6. With a complete lubrication system, it will automatically shut down when the temperature is too high or the flow rate is too slow.

7. The internal structure has good sealing performance, which can effectively protect the equipment from dust and other small particles.

8. Long service life and strong applicability.

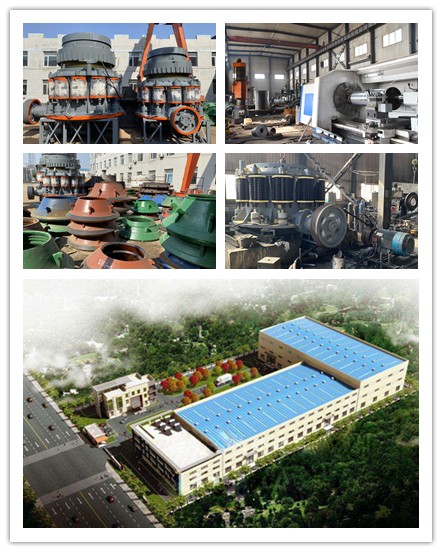

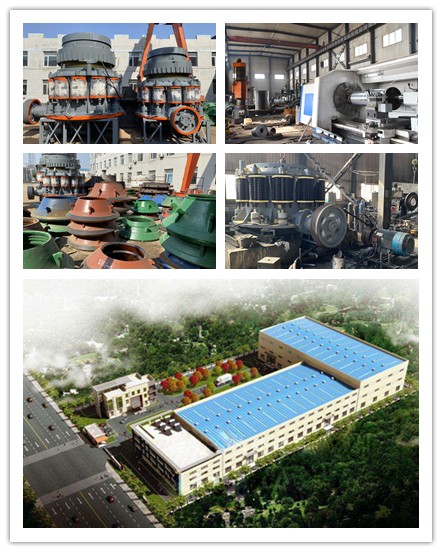

ShiLong Company Profile

Shenyang ShiLong Mechanical Manufacturing Co., Ltd. was established in 2000. It is a comprehensive enterprise dedicated to the production of mining machinery and spare parts.

As a manufacturing enterprise focusing on mining equipment and products, ShiLong is committed to building a global professional manufacturing factory. Shilong has more than 300 lathes, boring machines, milling machines and various CNC processing equipment and has more than 30 professional and technical personnel! And has a large warehouse of nearly 3000 square meters.

For 20 years, ShiLong has manufactured more than 1,000 kinds of mining equipment and related spear parts for more than 3,000 domestic enterprises and foreign trade companies. The products mainly cover multi-cylinder hydraulic cone crusher, heavy hydraulic cone crusher, single-cylinder hydraulic cone crusher, symons cone crusher, jaw crusher, gyratory crusher, ball mill, high-pressure roller mill and their spear parts.

The product quality is reliable, the performance is good, has won widespread praise.

ShiLong looks forward to working with you to create the future together!

ShiLong Company Packing and Transport

Shilong attaches great importance to packaging. Especially products exported to foreign trade.

Before packaging, we will strictly inspect and handle all mechanical parts. Minimize the failure rate of products.

For transportation, we can meet all the transportation requirements of our customers.

Shilong's ultimate goal is to build a world-class professional manufacturing plant. We will work tirelessly for this goal.

ShiLong Company Spare Parts Store

ShiLong has ready-made finished products stored in inventory whose area is nearly 3000 square meters. We can ship directly, eliminating the production period.

For the jaw crusher parts, we can manufacture single toggle jaw crusher, double toggle jaw crusher, mesto c-series jaw crusher,jaw crusher shaft, jaw crusher movable jaw, jaw crusher bearing, jaw crusher toggle plate, jaw crusher toggle plate seats, jaw crusher fixed jaw plate, jaw crusher flywheel, jaw crusher frame, jaw crusher tension rod, etc.

For the cone crsuher parts, we can manufacture symons cone crusher, spring cone crusher,GP series cone crusher, HP series cone crusher, copound cone crusehr, gyratory crusher, and their spare parts including : cone crusher main frame, cone crusher main frame liner, cone crusehr countershaft, cone crusher countershaft bushing, cone crusher countershaft box, cone crusher thrust washer, cone crusher socket, cone crusher socket liner, cone crusher socket sealing ring, cone cruehr pinion, cone crusher pulley, cone crusher main shaft, cone crusher counterweight, cone crusher eccentric , cone crusher innner eccentric bushing, cone crusher outer eccentric bushing, cone crusher step plate, cone crusher feed distributor, cone crusher spring, cone crusher gear, cone crusher adjustment gear, cone crusher adjustment drivend box, cone crusher hydraulic motor, cone crusher adjustment ring, cone crusher adjustment cap, cone crusher head, cone crusher concave, cone crusher mantle, cone crusher relief cylinder, cone cruehr shaft nut cap, cone crusher bowl, cone crusher feed cone, cone crusher hopper, cone crusher baffle ring, cone crusher lubrication system, etc .

For ball mill parts, we can manufacture ball grinder mill, ball mill gear, ball mill pinion, ball mill coupling, ball mill shaft, ball mill reducer, ball mill shell, ball mill liners, ball mill bearing, ball mill bearing seat, ball mill feeder, ball mill feeder cap, ball mill seal ring, ball mill discharge, ball mill discharge cap ball mill bearing cover, etc.

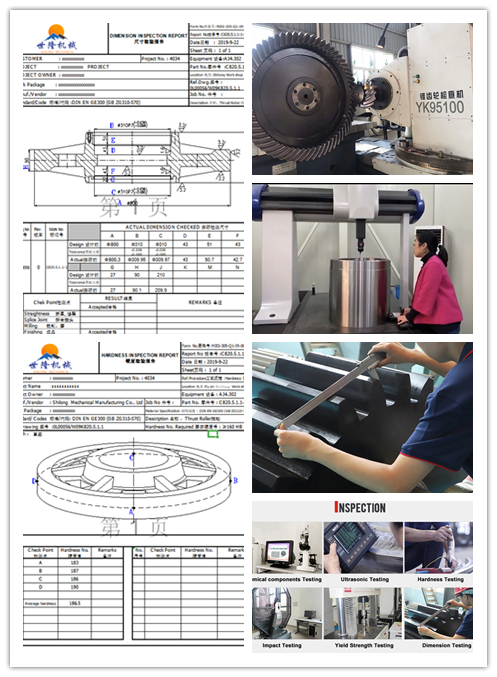

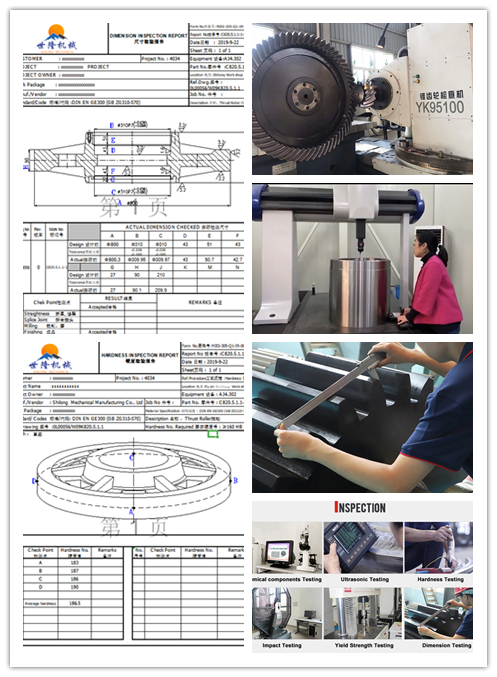

ShiLong Company Inspection

Shilong has over 20 years of experience in the field of crusher and mill spare parts. For product inspection, Shilong requires everyone to implement the principle of one inspection per product and one number per product. There are an independent file and after-sale tracking for each one factory product. We hope to do quality control in every detail.

For every product, For each product, we do strict quality inspection and establish product files. After the quality inspection is completed, we provide an accurate quality inspection report.

We hope to be able to do it truly: Shilong only product high-quality products. And all the products produced by Shilong must be good quality products.