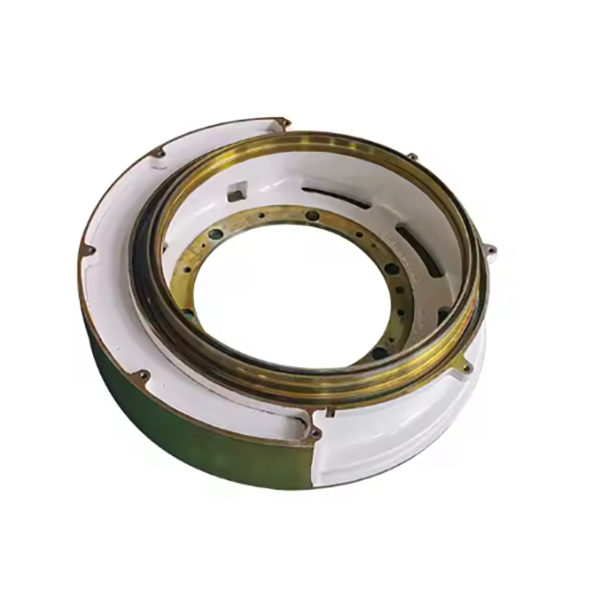

Cone Crusher dust shell

The cone crusher dust shell, a protective component at the crusher's upper part, prevents dust, debris, and moisture from entering internal parts (e.g., adjustment gear, thrust bearing), enhances safety by blocking access to moving components, and reduces noise. It operates in harsh, dusty environments, requiring durability and a tight seal.

Structurally, it includes a thin-walled shell body (mild steel, stainless steel, or cast iron), upper/lower flanges with seals, reinforcement ribs, inspection doors, optional ventilation holes, and lifting lugs.

Manufacturing processes vary by material: mild/stainless steel shells undergo cutting, rolling, welding, and finishing; cast iron shells use sand casting and heat treatment. Machining focuses on flange flatness and seal surfaces, with surface treatments like painting or passivation.

Quality control involves material testing, dimensional checks, structural integrity tests (weld inspection, pressure testing), functional tests (seal performance, impact resistance), and assembly validation. These ensure the dust shell reliably protects internal components, supporting the crusher's efficient operation

More