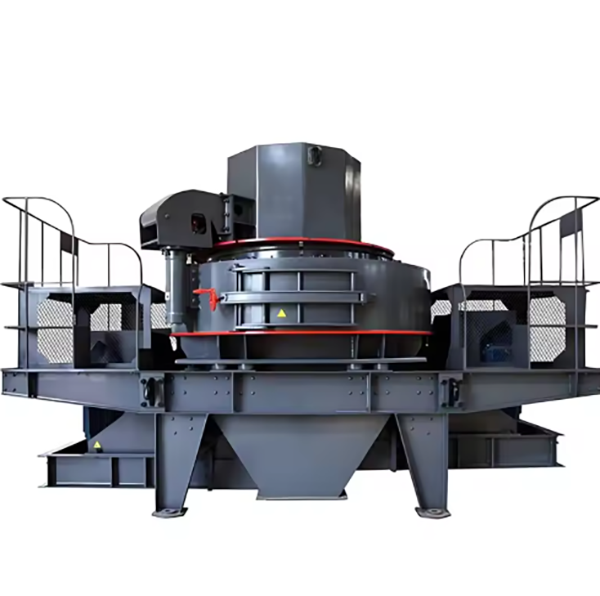

mobile cone crusher

The mobile cone crusher integrates a cone crusher, feeding/screening devices, conveyors, and a mobile chassis, designed for on-site crushing of medium to hard materials (granite, basalt, etc.) with high mobility. It features a mobile chassis (frame, axles/wheels, hydraulic jacks), cone crusher unit (crushing chamber, eccentric shaft, motor), feeding/screening system, conveyors, and hydraulic/electrical controls, with a processing capacity of 50–500 t/h.

Manufacturing involves welding and machining the Q355B steel chassis, casting (high-chromium cast iron for cones, ZG35CrMo for eccentric shafts) with heat treatment, and assembling components. Quality control includes material testing, dimensional inspection, performance tests (no-load/load/mobility), and safety checks. Installation requires site preparation, transportation, leveling, and commissioning. Widely used in mining, road construction, and infrastructure, it delivers uniform, high-cubicity aggregates efficiently

More