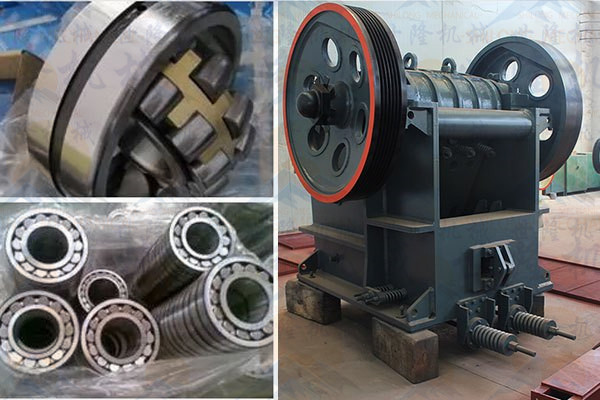

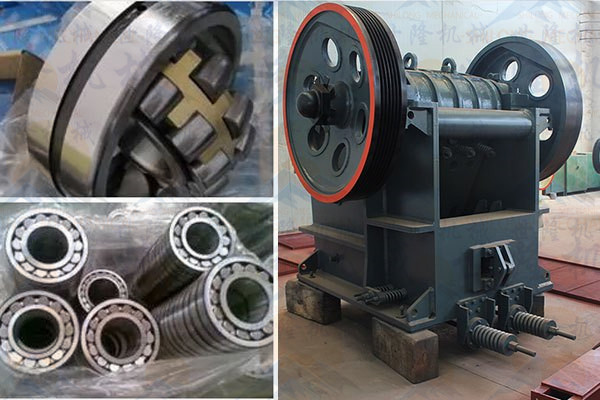

Bearings are core components in jaw crushers that enable rotational motion and load-bearing functionality. They are primarily installed at the connections between the eccentric shaft and the swing jaw bearing housing, as well as between the main shaft and the frame. Bearings convert the rotational motion of the eccentric shaft into the oscillating motion of the swing jaw while withstanding radial and axial loads generated during crushing. Their performance directly impacts the crusher’s operational precision, energy consumption, and service life, requiring high load capacity, wear resistance, and impact resistance.

Jaw crushers commonly use double-row spherical roller bearings (for large machines) or self-aligning roller bearings (for small and medium-sized machines). Their composition and structural features are as follows:

Inner Ring

A ring-shaped component with an interference fit on the eccentric shaft. The inner diameter of the inner ring forms a tolerance fit with the shaft (typically H7/k6). Its outer surface is machined with a raceway (spherical or arc-shaped) to guide roller movement. Both sides of the inner ring have flanges to restrict axial displacement of the rollers; the flange height matches the roller length (usually 1/3–1/2 of the roller diameter) to ensure uniform force distribution.

Outer Ring

A ring-shaped component with a transition fit in the swing jaw bearing housing or frame bore. The outer diameter of the outer ring forms a tolerance fit with the bearing housing bore (typically J7/h6). Its inner surface features a spherical raceway corresponding to the inner ring, with the raceway’s center of curvature coinciding with the bearing axis. This allows the inner ring to angularly displace relative to the outer ring by ±2°–3° (compensating for installation errors or shaft deflection).

Rolling Elements

Load-bearing components between the inner and outer rings, mostly barrel-shaped (spherical) rollers. The number varies by bearing size (8–12 for small/medium bearings, 15–20 for large ones). Rollers are precision-ground (surface roughness Ra ≤ 0.4 μm) and made of high-strength chromium bearing steel (GCr15SiMn), offering high hardness (60–65 HRC) and wear resistance to withstand radial impact loads.

Cage

A framework separating and guiding the rolling elements, made of brass (H62), stamped steel (SPCC), or reinforced nylon (PA66+GF25). Large bearings often use solid brass cages (for high strength), while small/medium bearings use stamped steel cages (for lightweight design). Cages feature "window-type" or "wave-type" structures to ensure uniform roller distribution and prevent mutual friction.

Sealing Device

Contamination-resistant components at both ends of the bearing, consisting of sealing rings (nitrile rubber or fluororubber) and dust covers. Sealing rings form an interference fit with the inner ring, with lips 紧贴 the outer ring’s inner side to prevent lubricant leakage and ingress of dust/water (critical for dusty crushing environments, requiring IP54 or higher protection).

Raw Material Preparation

Forging

Round bars are heated to 850–900°C and die-forged into ring-shaped (inner ring) or cup-shaped (outer ring) forgings via upsetting, punching, and expanding. Forgings are air-cooled to maintain continuous grain flow (enhancing fatigue resistance).

Heat Treatment (Intermediate)

Spheroidizing annealing: Heating to 780–800°C, holding for 3–4 hours, then slow cooling to 600°C for air cooling. This spheroidizes carbides, reducing hardness to 207–255 HBW and improving machinability.

Rough Machining

Turning: CNC lathes machine inner/outer diameters, end faces, and flanges of inner/outer rings, leaving 1–2 mm finishing allowance. End face parallelism is ≤ 0.1 mm/100 mm, and inner/outer diameter coaxiality is ≤ 0.05 mm.

Drilling (outer ring): Lubrication holes (3–5 mm diameter) are drilled in the outer ring flange, with position tolerance ±0.5 mm to align with bearing housing oil passages.

Heat Treatment (Final)

Quenching: Heating to 830–860°C, oil quenching (cooling rate ≥ 50°C/s) to achieve 61–65 HRC for inner/outer rings.

Low-temperature tempering: Holding at 150–180°C for 2–3 hours to relieve quenching stress and stabilize microstructure (retained austenite ≤ 5%).

Finish Machining

Grinding: Centerless grinders machine outer diameters, internal grinders machine inner diameters (IT5 tolerance), surface grinders machine end faces (parallelism ≤ 0.01 mm/100 mm), and raceway grinders machine spherical raceways (surface roughness Ra ≤ 0.1 μm, curvature radius deviation ≤ 0.005 mm).

Superfinishing: Raceways are superfinished (removing 0.005–0.01 mm) to reduce roughness to Ra ≤ 0.025 μm, improving contact precision and wear resistance.

Cold Heading

Heat Treatment

Grinding and Superfinishing

Brass cages: Machined from brass bars via turning and milling into window-type structures, with window dimensional tolerance ±0.05 mm to ensure 0.1–0.2 mm clearance with rollers.

Stamped steel cages: Formed from SPCC sheets via stamping, with deburred window edges and zinc-plated surfaces (8–12 μm thickness) for rust resistance.

Raw Material Inspection

Chemical analysis: Spectrometry verifies GCr15 composition (C: 0.95–1.05%, Cr: 1.3–1.65%, P ≤ 0.025%, S ≤ 0.025%).

Non-metallic inclusion testing: Rating ≤ 2.5 (per GB/T 10561) to avoid large inclusions causing premature failure.

Dimensional Accuracy Inspection

Inner/outer rings: Coordinate measuring machines verify inner/outer diameters and raceway curvature (deviation ≤ 0.005 mm). Roundness testers check roundness (≤ 0.001 mm).

Rolling elements: Laser diameter gauges verify diameter (tolerance ±0.002 mm) and dimensional consistency (deviation ≤ 0.003 mm).

Mechanical Property Testing

Hardness testing: Rockwell hardness testers verify 61–65 HRC for rings and 62–66 HRC for rollers, with hardness uniformity ≤ 3 HRC.

Impact toughness: Sampling for -40°C impact tests (impact energy ≥ 20 J) to ensure low-temperature toughness.

Surface Quality Inspection

Magnetic particle testing (MT): Detects surface cracks on rings/rollers (length ≤ 0.5 mm), excluding folds or scratches.

Roughness testing: Laser interferometers verify raceway roughness (Ra ≤ 0.1 μm) and superfinished Ra ≤ 0.025 μm.

Assembly Quality Inspection

Clearance testing: Specialized instruments measure radial clearance (per GB/T 4604, deviation ±5 μm).

Rotational accuracy: Bearing testers check radial runout (≤ 0.01 mm) and axial movement (≤ 0.02 mm) at rated speed.

Life Verification

With strict process control, bearings operate reliably under high loads and impacts, with a service life of 8000–12000 hours (depending on lubrication and maintenance). Regular lubrication checks (oil film thickness ≥ 5 μm) are critical to prevent bearing burnout from oil starvation or contamination

The bearing is an important part of the jaw crusher. Generally, rocket roller bearings are used. The specific model of the bearing can be determined from the three aspects of bearing size, bearing accuracy and bearing internal clearance.

A Bearing size

The size of the eccentric shaft is calculated from the crushing force. After the journals of the eccentric shaft at the frame bearing and the movable jaw bearing are initially determined, the bearing specifications are initially determined based on this, and the medium-width series specifications are usually selected as much as possible to check the theoretical service life of the bearing To meet relevant standards.

B Bearing Accuracy

Bearing accuracy includes two aspects: dimensional tolerance and rotation accuracy, whether it is the geometric tolerance of each component of the bearing or the radial and axial runout errors during rotation, because the jaw crusher moves at a spindle speed lower than 300r/mim , So ordinary precision bearings can meet the requirements.

C Bearing internal clearance

Rocket roller bearings only have radial clearance. According to the standard, the radial clearance is divided into five groups, which have been selected and adjusted by the manufacturer before leaving the factory. At this time, the clearance is called the original clearance. After the bearing is assembled, its original clearance will be reduced. For the movable jaw bearing, the eccentric shaft is assembled with it by interference fit. After the movable jaw bearing is heated, the inner ring is expanded and mounted on the eccentric shaft. The expansion of the inner ring will reduce the original clearance of the bearing.

2. Jaw crusher bearings-wear

If the shaft wears very little, it can be turned on a lathe to make the journal to the correct geometric shape just to repair its geometric shape. Then reduce the bearing inner diameter accordingly. However, if the journal size is reduced by 5% compared to the original after several such treatments, turning is not allowed and a new shaft should be replaced.

3. Jaw crusher bearing-installation

a. Check for rust before installation. You can clean it with diesel or kerosene. Then check whether the radial clearance of the bearing, the size and accuracy of the inner hole, and the size of the eccentric shaft assembly journal meet the requirements.

b. Due to the large amount of journal surplus (to the maximum that can be accommodated or withstood) of the equipped bearing, it is generally installed by the hot-fixing method. The bearing is heated to a temperature of about 100°C, and the shaft hole expands to be larger than the journal size After that, the assembly can be carried out. The hot-loading method uses an oil bath for heating, which can ensure that all parts of the bearing are evenly heated without deforming it or reducing its hardness.

c. After the bearing is assembled, use a feeler gauge to check the radial clearance of the bearing after fully cool. Please find the cause in time if it is too small or there is no clearance. If the cause cannot be found, it must be removed and reassembled. If the clearance is appropriate, grease can be applied, and then the other parts can be assembled.