The toggle plate (thrust plate) is a critical force-transmitting component connecting the movable jaw and frame in jaw crushers, while also serving as a key overload protection device, known as the "safety fuse" of the equipment. During operation, it converts the rotational motion of the eccentric shaft into the reciprocating swing of the movable jaw, driving the movable jaw and fixed jaw to periodically close for material crushing. When uncrushable hard objects (e.g., iron blocks) enter the crusher, causing a sudden load increase, the toggle plate fractures under excessive stress, 切断 power transmission to protect core components such as the frame and eccentric shaft from damage.

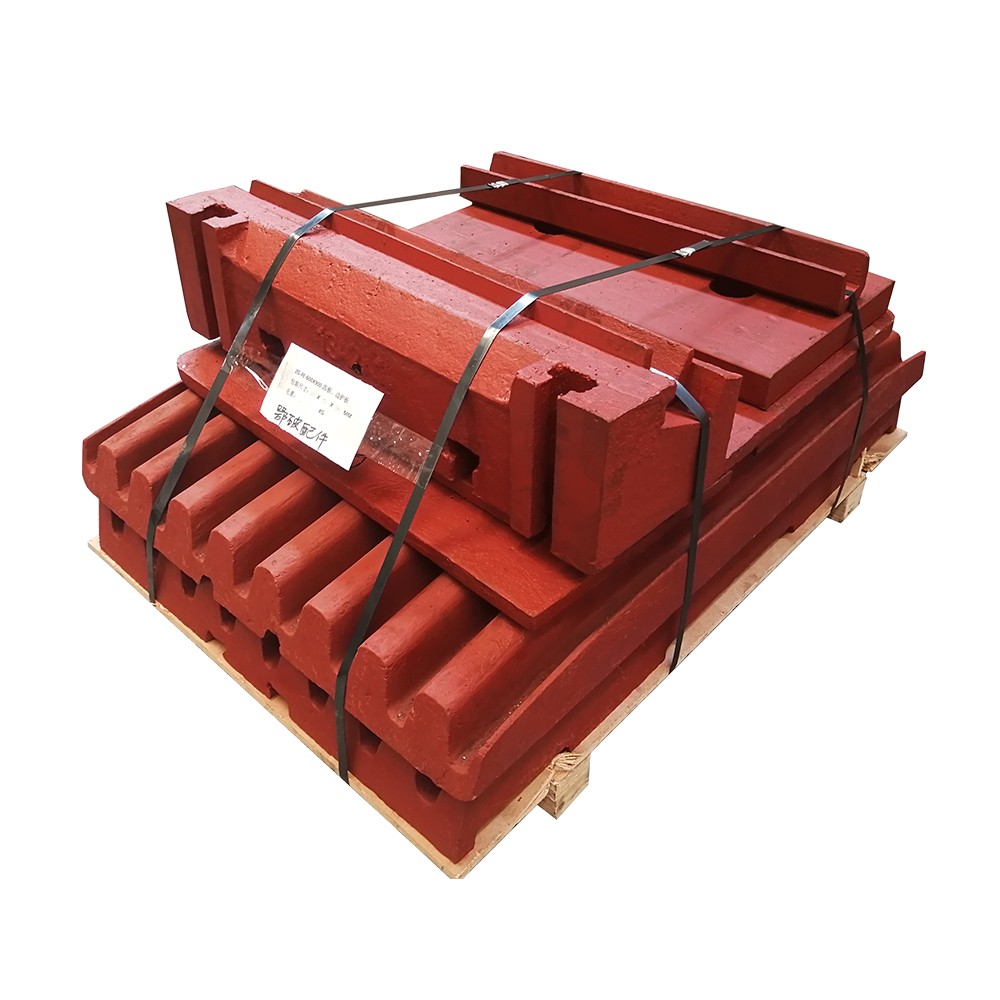

The toggle plate has a relatively simple structure, generally in a plate or wedge shape. Depending on the crusher model, it can be divided into integral toggle plates and combined toggle plates (composed of upper/lower toggle plates and connecting bolts, commonly used in large crushers). Its core structure includes:

Body: The main body is a flat plate, with arc or flat surfaces at both ends—called "support ends"—that mate with the "toggle plate seats" on the movable jaw and frame. The curvature radius of these support ends must precisely match the seats to ensure uniform force distribution.

Reinforcing Ribs: Longitudinal reinforcing ribs are cast on both sides of the body in some large toggle plates to enhance overall rigidity, preventing premature fracture due to excessive bending stress during operation.

Weakening Grooves/Stress Concentration Grooves: Grooves designed in the middle or specific positions of the toggle plate to reduce local strength, ensuring controlled fracture (usually in the middle) during overload, which facilitates replacement and avoids damage to other components from fracture fragments.

Connecting Holes (for Combined Toggle Plates): The upper and lower parts of combined toggle plates are connected by bolts, with positioning holes machined at the joints to ensure coaxiality and perpendicularity during assembly.

Toggle plates are typically made of gray cast iron (HT200, HT250) or malleable cast iron (KT350-10). Gray cast iron, with low cost and moderate brittleness (meeting overload fracture requirements), is suitable for small-to-medium crushers. Malleable cast iron, with higher toughness, is used in large crushers to withstand greater impact forces.

The casting process of the toggle plate must balance the material’s strength and brittleness, ensuring stable force transmission during normal operation and reliable fracture during overload. The specific process is as follows:

Mold Preparation

Sand casting (green sand or resin sand) is adopted. Wooden or metal patterns are made based on toggle plate drawings, accurately replicating the body, reinforcing ribs, and weakening grooves, with a 2–3 mm machining allowance reserved (gray cast iron has a shrinkage rate of ~0.8–1%).

The sand mold cavity surface must be smooth to avoid sand holes on the casting. Vent channels are added on the parting surface to prevent gas entrapment and porosity during pouring.

Melting and Pouring

Gray cast iron melting: Pig iron, scrap steel, and return scrap are proportioned, melted in a cupola or medium-frequency furnace at 1380–1420°C. Chemical composition is controlled (C: 3.0–3.4%, Si: 1.8–2.2%, Mn: 0.5–0.8%, S ≤0.12%, P ≤0.2%) to balance strength and brittleness (excessive Si reduces brittleness, potentially preventing fracture during overload).

Malleable cast iron is first cast as white iron (with reduced carbon equivalent to avoid graphite formation), followed by annealing to obtain a ductile structure.

An open pouring system is used to ensure smooth flow of molten metal into the cavity, avoiding slag entrainment. For toggle plates with reinforcing ribs, the pouring rate is controlled at 5–8 kg/s to prevent cold shuts in the ribs.

Shakeout and Cleaning

The casting is shakeout after cooling to below 300°C. Risers and gates are removed (small toggle plates by knocking, large ones by flame cutting), and gate marks are ground smooth.

Surface sand and burrs are cleaned, with key areas (support ends, weakening grooves) inspected to ensure no obvious defects.

Heat Treatment

Gray cast iron toggle plates: Stress relief annealing is performed (heated to 500–550°C, held for 2–3 hours, then furnace-cooled to 200°C) to eliminate casting stress and prevent deformation during machining or operation.

Malleable cast iron toggle plates: Graphitizing annealing is conducted (heated to 900–950°C, held for 3–5 hours, then slowly cooled to 700°C before air cooling) to decompose cementite into nodular graphite, achieving the required toughness (tensile strength ≥350 MPa, elongation ≥10%).

The machining accuracy of the toggle plate directly affects its fitting stability with the movable jaw and frame, as well as force transmission efficiency. The specific process is as follows:

Rough Machining

Using the outer circle of the support ends and the side surfaces as references, a milling machine or planer is used to machine the upper and lower planes (connecting surfaces of combined toggle plates), leaving a 1–2 mm finishing allowance to ensure flatness error ≤0.5 mm/m.

The arc surfaces of the support ends are rough-turned or rough-milled to ensure curvature radius deviation ≤0.5 mm, laying the foundation for subsequent finishing.

Finishing

Precision machining of support ends: A vertical milling machine or boring machine is used to machine the arc or flat surfaces of the support ends, ensuring a fitting gap with the toggle plate seats ≤0.1 mm (excessive gap causes noise and wear during operation), with surface roughness Ra ≤6.3 μm.

Weakening groove machining: An end mill is used to machine the middle weakening groove, with groove width and depth tolerance ±0.3 mm. The fillet radius at the groove bottom must meet drawing requirements (to avoid premature fracture due to excessively small fillets).

Connecting hole machining (for combined toggle plates): Bolt holes for connecting upper and lower toggle plates are drilled on a drilling machine, with hole position tolerance ±0.2 mm, hole wall roughness Ra ≤12.5 μm, and threads (thread accuracy 6H) tapped with a tap.

Surface Treatment

Machining burrs are removed. The mating surfaces of the support ends are phosphated (to enhance wear resistance), and non-mating surfaces are painted for rust prevention (paint film thickness 40–60 μm), ensuring no missed coating or sagging.

The quality of the toggle plate directly affects the operational stability and safety of the crusher. Multi-stage controls are implemented to ensure performance compliance:

Material Quality Control

Raw material inspection: Spectral analysis is performed on cast iron to verify chemical composition compliance (e.g., C content 3.0–3.4% for HT250 gray cast iron). Tensile tests are conducted on samples to ensure tensile strength (gray cast iron ≥250 MPa) and hardness (170–240 HBW) meet standards.

Metallographic inspection: Gray cast iron must have type A (flaky) graphite without network carbides. Malleable cast iron is checked for nodular graphite, avoiding white iron structures (which cause excessive brittleness).

Casting Quality Control

Visual defect inspection: 100% visual inspection is conducted to exclude cracks, shrinkage cavities, or through pores. Magnetic particle testing (MT) is performed on key areas (support ends, weakening grooves) to ensure no surface cracks.

Dimensional deviation inspection: Calipers and templates are used to check length and width deviations (≤±1 mm), and arc templates verify the fit of support end arcs (gap ≤0.3 mm).

Machining Accuracy Control

Geometric tolerance inspection: A dial indicator and straightedge are used to check flatness and perpendicularity (error ≤0.1 mm/100 mm). A coordinate measuring machine verifies the position accuracy of connecting holes (deviation ≤0.2 mm).

Weakening groove strength verification: Sampled finished toggle plates undergo pressure testing, with 1.5 times the rated working load applied to observe whether fracture occurs at the preset position (weakening groove) with a flat fracture surface and no splashing fragments.

Final Inspection Before Assembly

Trial fitting with toggle plate seats: The toggle plate is installed into the toggle plate seats of the movable jaw and frame, with a feeler gauge used to check the fitting gap, ensuring no jamming or looseness. The movable jaw should rotate flexibly when manually operated.

Label inspection: Finished products must be marked with model, material, and production date for traceability. Unqualified products are individually marked and isolated to prevent mixing with qualified ones.

Through strict casting, machining, and quality control processes, the toggle plate can ensure stable force transmission during normal operation and reliable overload protection. Its service life is typically 3–6 months (adjusted based on material hardness and crushing frequency), and regular replacement can effectively reduce crusher maintenance costs and failure risks