Multi-cylinder Hydraulic Cone Crusher

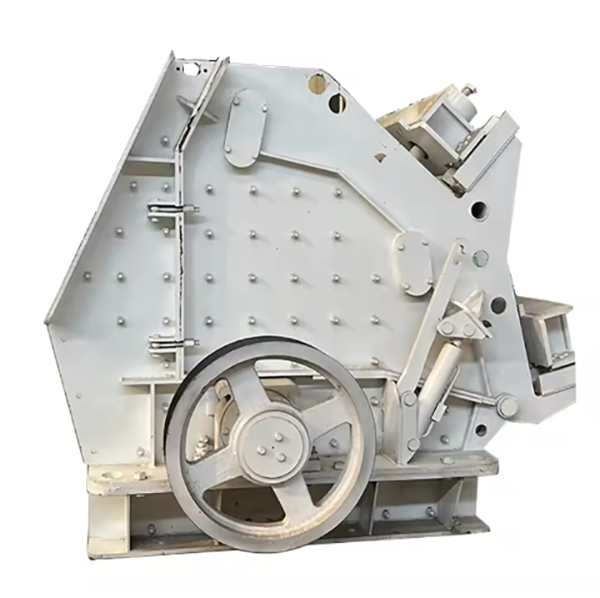

The multi-cylinder hydraulic cone crusher, an advanced equipment for medium-to-fine crushing of hard/ultra-hard materials (granite, basalt, etc.), utilizes "lamination crushing" technology. Driven by a motor, its eccentric shaft sleeve rotates to make the moving cone oscillate, crushing materials between the moving and fixed cones into uniform particles, with a capacity of 50–2000 t/h, widely used in mining, construction aggregates, etc.

Structurally, it includes: main frame assembly (upper frame ZG270-500, lower frame ZG35CrMo); crushing assembly (42CrMo moving cone with Cr20/ZGMn13 liner, segmented fixed cone); transmission assembly (ZG35CrMo eccentric shaft sleeve, 20CrMnTi bevel gears); 6–12 hydraulic cylinders for discharge port adjustment (5–50 mm) and overload protection; plus lubrication (ISO VG 46 oil) and dustproof systems.

Key components undergo precise manufacturing: casting (frames, eccentric sleeve) with heat treatment; forging (moving cone) and CNC machining. Quality control involves material testing (spectrometry, tensile tests), dimensional inspection (CMM, laser scanning), NDT (UT, MPT), and performance tests (dynamic balancing, 48-hour crushing run).

Its advantages lie in high efficiency, excellent product cubicity (≥85%), reliable hydraulic safety, and adaptability to tough materials, serving as core equipment in modern crushing lines

More