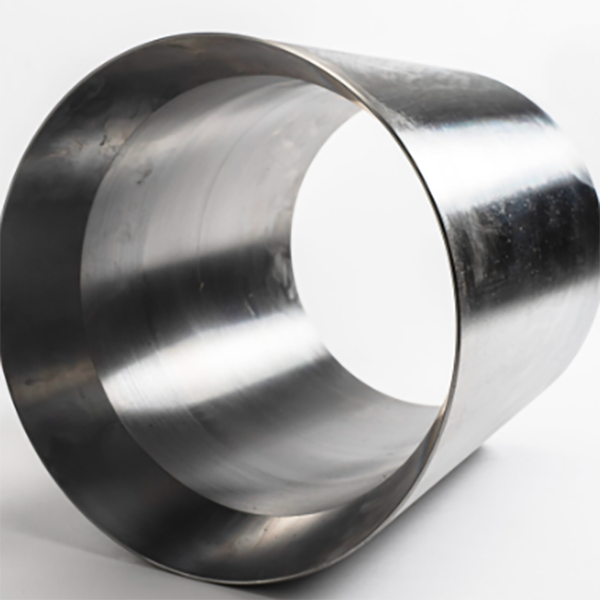

Cone Crusher head

This paper details the cone crusher head, a core crushing component that works with the fixed cone to crush materials through oscillating motion, with its performance directly affecting throughput, product granularity, and wear resistance. It outlines its composition, including the head body (core structure), wear liner (mantle), bearing bore, mounting features, and ventilation/weight reduction cavities, along with their structural characteristics. The casting process for the head body is elaborated, covering material selection (cast steel or ductile iron), pattern making, molding, melting, pouring, heat treatment, and inspection. It also describes the machining of the head body and wear liner, as well as assembly steps. Additionally, quality control measures are specified, such as material testing, dimensional accuracy checks, wear resistance testing, assembly and performance testing, and non-destructive testing. These processes ensure the head has high strength, wear resistance, and dimensional accuracy, guaranteeing reliable performance in heavy-duty crushing operations.

More