Cone Crusher Hopper

This paper elaborates on the Cone Crusher Hopper component, a crucial material guiding part located at the top of the crusher. Its main functions include material collection and storage, uniform distribution, impact buffering, and contamination prevention, requiring high wear resistance, structural strength, and corrosion resistance.

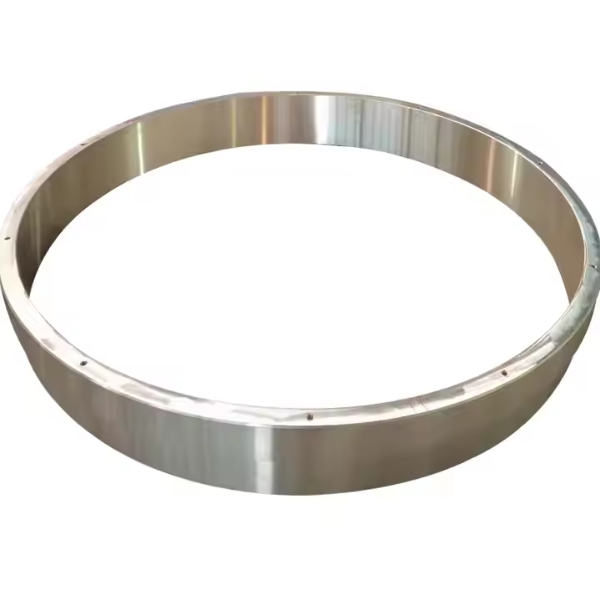

The hopper is typically funnel-shaped or rectangular, composed of the hopper body, feed grate/screen, wear liners, reinforcing ribs, mounting flange, access door, and optional vibration device mounts, each with specific structural features and roles.

For cast steel variants, the casting process involves material selection (high-strength cast steel like ZG270–500), pattern making, molding, melting and pouring, cooling and shakeout, heat treatment, and casting inspection. Most hoppers, however, are fabricated from steel plates through plate cutting, forming and bending, welding assembly, post-weld treatment, machining of mounting features, liner installation, and surface treatment.

Quality control processes cover material validation, dimensional accuracy checks, weld quality inspection, structural integrity testing, liner performance testing, and final inspection. These ensure the hopper can withstand abrasive wear and impact, guaranteeing continuous and efficient operation of the cone crusher in relevant applications.

More