Cone Crusher Mantle

The cone crusher mantle, also known as the moving cone liner, is a critical wear-resistant component mounted on the outer surface of the moving cone, forming the rotating part of the crushing chamber. Its main functions include active crushing (rotating eccentrically with the bowl liner to reduce materials), wear protection (shielding the moving cone), material flow control (guiding materials through the crushing chamber via its tapered profile), and force distribution (ensuring even force distribution to minimize localized wear). It requires exceptional wear resistance (hardness ≥HRC 60), impact toughness (≥12 J/cm²), and dimensional stability.

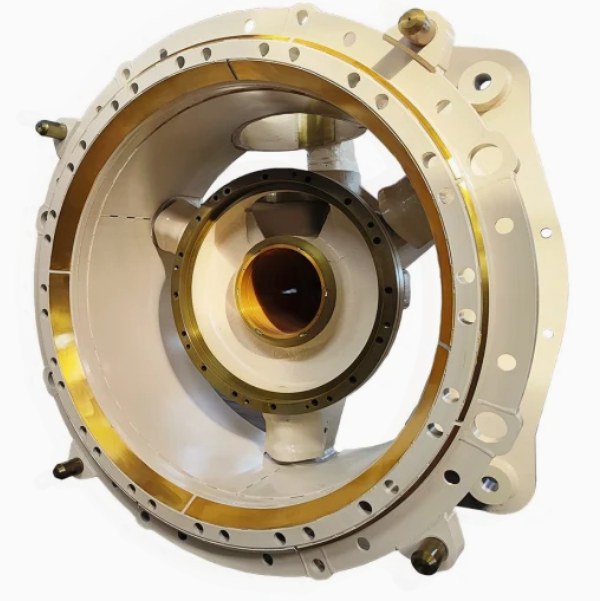

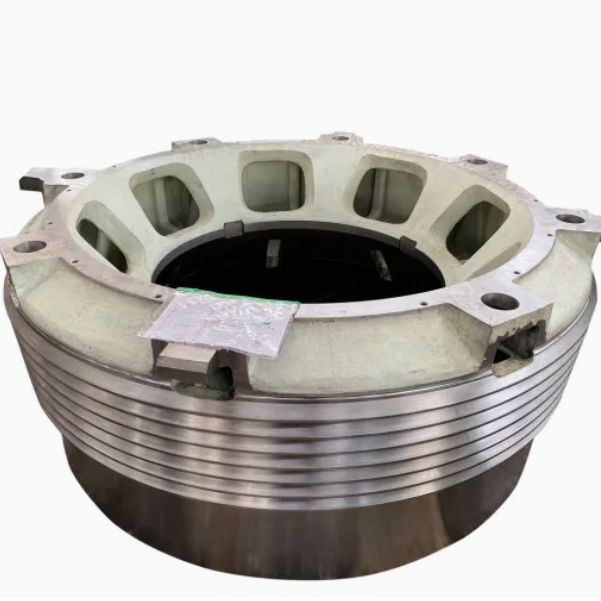

Structurally, it is a conical or frustoconical component consisting of the mantle body (high-chromium cast iron like Cr20–Cr26 or nickel-hard cast iron), outer wear profile (with 15°–30° taper angle, ribbed/grooved surfaces, and smooth transition zones), mounting features (conical inner surface, bolt flange, locking nut interface, locating keys), reinforcement ribs, and chamfered/rounded edges.

The casting process involves material selection (high-chromium cast iron Cr20Mo3), pattern making (with shrinkage allowances), molding (resin-bonded sand mold), melting and pouring (controlled temperature and flow rate), and heat treatment (solution annealing and austempering). The machining process includes rough machining, precision machining of the inner surface, mounting feature machining, outer profile finishing, and surface treatment.

Quality control covers material testing (chemical composition and metallographic analysis), mechanical property testing (hardness and impact testing), dimensional accuracy checks (using CMM and laser scanner), non-destructive testing (ultrasonic and magnetic particle testing), and wear performance validation (accelerated testing and field trials). These ensure the mantle achieves the required wear resistance, precision, and durability for efficient cone crusher operation in mining, quarrying, and aggregate processing

More