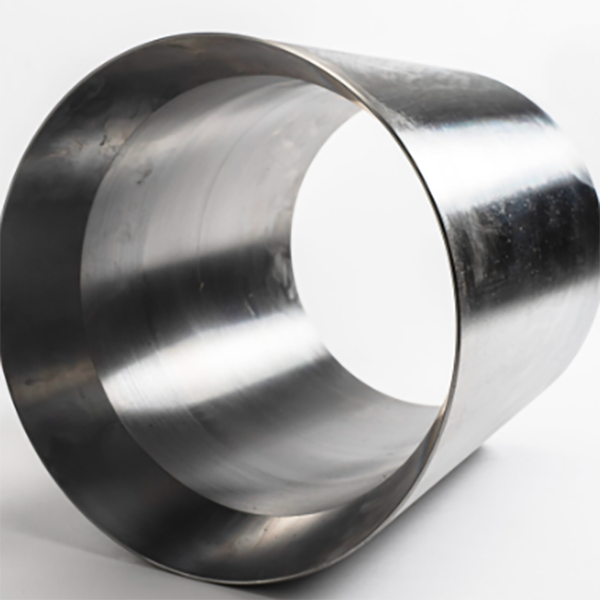

Cone Crusher main shaft nut

The cone crusher main shaft nut, a critical fastener at the top or bottom of the main shaft, secures components like the main shaft bearing, eccentric bushing, and moving cone. Its primary functions include axial fixation (preventing displacement from vibration and loads), load transfer (distributing axial loads up to hundreds of kilonewtons), bearing preload adjustment, and contamination prevention.

Structurally, it is a large heavy-duty fastener with a cylindrical or hexagonal profile, consisting of the nut body (high-strength alloy steel 42CrMo/35CrMo or cast steel ZG35CrMo), internal threads (class 6H tolerance, M30–M100 coarse-pitch), locking mechanisms (locking slots, tapered interface, set screw holes), torque application surface, seal groove, and shoulder/flange.

For large nuts (outer diameter >300 mm), the casting process involves material selection (ZG35CrMo), pattern making (with shrinkage allowances), molding (green sand or resin-bonded sand), melting and pouring (controlled temperature and flow), cooling and shakeout, and heat treatment (normalization and tempering). The machining process includes rough machining, thread machining, locking feature machining, heat treatment for hardening (induction-hardened threads to HRC 45–50), finish machining, and surface treatment.

Quality control covers material testing (chemical composition and hardness), dimensional checks (CMM and thread gauges), structural integrity testing (MPT and UT), functional testing (torque and vibration tests), and seal performance testing. These ensure the main shaft nut provides reliable fixation, enabling stable cone crusher operation under heavy loads and high vibrations

More