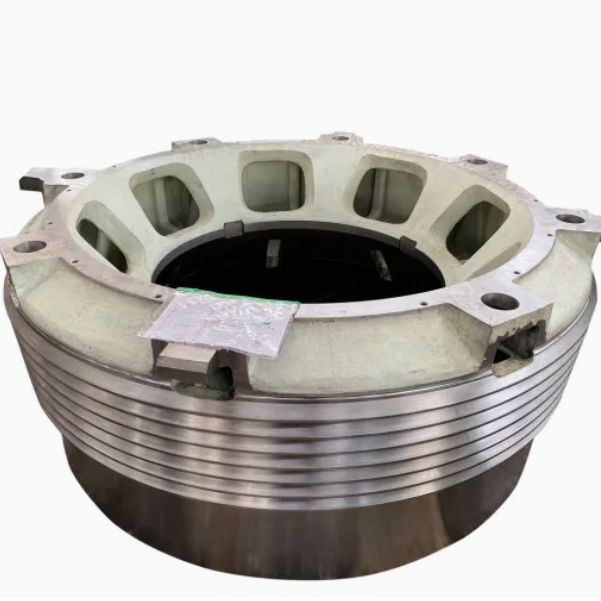

Cone Crusher Concave

The cone crusher concave, also called the fixed cone liner or bowl liner, is a key wear-resistant component mounted on the inner surface of the bowl, forming the stationary part of the crushing chamber. Its main functions include material crushing (cooperating with the rotating mantle), wear protection (shielding the bowl), material flow guidance (via its inner profile), and product size control (influenced by inner geometry). It needs exceptional wear resistance (surface hardness ≥HRC 60), impact toughness (≥12 J/cm²), and structural integrity to withstand continuous material impact.

Structurally, it is a segmented (3–8 pieces for large crushers) or one-piece conical component. It consists of concave segments/one-piece structure, a wear-resistant body (high-chromium cast iron Cr20–Cr26 or Ni-Hard 4), an inner wear profile (tapered design with 15°–30° angle, ribs/grooves, parallel sections), mounting features (dovetail tabs, clamping holes, locating pins), outer backing (in bimetallic designs), and top/bottom flanges.

The casting process for high-chromium cast iron concaves involves material selection (Cr20Mo3 with controlled composition), pattern making (segmented patterns with shrinkage allowances), molding (resin-bonded sand mold with refractory wash), melting and pouring (induction furnace, controlled temperature and flow rate), and cooling and heat treatment (solution annealing and austempering). The machining process includes rough machining, mounting feature machining, inner profile finishing, segment assembly (for multi-piece designs), and surface treatment.

Quality control processes cover material testing (chemical composition and metallographic analysis), mechanical property testing (hardness and impact testing), dimensional accuracy checks (CMM and laser scanner), non-destructive testing (UT and MPT), and wear performance validation (accelerated testing and field trials). These ensure the concave achieves the required wear resistance, precision, and durability for efficient, long-term crushing performance in mining, quarrying, and aggregate processing

More