The PE series jaw crusher (where "PE" stands for "Primary Crusher") is the most commonly used primary crushing equipment in industries such as mining, construction, and metallurgy. Renowned for its simple structure, large crushing ratio (typically 4–6), and wide adaptability to material hardness (capable of crushing ores and rocks with compressive strength ≤320 MPa), it serves as the "first-stage core" in material crushing production lines. Operating on the principle of "compressive crushing," it reduces large materials to a particle size suitable for subsequent processing (discharge opening adjustable from 10–300 mm) through the periodic opening and closing of the moving and fixed jaws.

The structure of PE series jaw crushers consists of five core components: main frame, crushing mechanism, transmission system, adjustment device, and safety device. These components work together to achieve efficient material crushing, with specific functions as follows:

Main Frame

As the foundational load-bearing structure, it is made of integral cast steel (ZG270-500) or high-strength welded steel (Q355B plates, 20–50 mm thick), withstanding massive impact forces during crushing (frame weight ranges from 5–50 tons, depending on the model).

The frame features a "U" shape, with side plates connecting the front wall (fixed jaw mounting surface) and rear wall (transmission system support surface). It encloses the crushing chamber and includes a discharge opening and support legs (secured to concrete foundations) at the bottom.

Crushing Mechanism

Fixed Jaw: Bolted to the front wall of the frame, its surface is fitted with a fixed jaw plate (ZGMn13 high manganese steel or Cr26 high chromium cast iron) 50–150 mm thick, with tooth-shaped grooves (8–15 mm high) to enhance material gripping.

Moving Jaw: A swing component suspended from the eccentric shaft, made of cast steel (ZG35CrMo) or welded structure, with a moving jaw plate mounted on its surface. It forms a "V" shaped crushing chamber with the fixed jaw, crushing materials via reciprocating motion.

Jaw Plate Fixing Device: Jaw plates are secured to the moving/fixed jaws using 8.8-grade high-strength T-bolts, with bolt heads recessed to avoid wear from material contact.

Transmission System

Motor: A three-phase asynchronous motor (5.5–250 kW, model-dependent) provides power, connected to the pulley via V-belts.

Pulley & Eccentric Shaft: The pulley (HT300 gray cast iron) transfers motor power to the eccentric shaft (40Cr steel, quenched and tempered to 28–32 HRC). The eccentric design converts rotational motion into reciprocating swing of the moving jaw (200–300 cycles/min).

Bearings & Bearing Blocks: Spherical roller bearings (e.g., model 23156) support the eccentric shaft in ductile iron (QT500-7) bearing blocks, ensuring stable rotation.

Adjustment Device

Used to regulate the discharge opening size, PE series primarily adopt shim adjustment: adding/removing shims between the frame and toggle plate seat changes the minimum gap between jaws. Adjustment ranges vary by model (e.g., PE900×1200: 95–165 mm). Large models (e.g., PE1200×1500) may use hydraulic adjustment for easier operation.

Safety Device

Protects against overload from uncrushable materials (e.g., iron blocks) via a toggle plate (HT200 cast iron, designed as a "weak link"). When overloaded, the toggle plate fractures, interrupting power transmission to prevent damage to critical components.

Manufacturing PE series jaw crushers requires balancing structural strength and operational stability, with core processes including frame fabrication, key component machining, assembly, and commissioning:

Frame Fabrication

Material & Forming: Small-to-medium models use welded Q355B steel plates (preheated to 150–200°C before welding), while large models use integral ZG270-500 castings (poured at 1520–1560°C, slow-cooled to ≤200°C).

Welding/Casting Quality: Welded frames undergo UT inspection (no cracks or incomplete fusion); cast frames are annealed (650–700°C for 4 hours) to relieve stress.

Machining: Bearing block bores are precision-bored to H7 tolerance (Ra ≤1.6 μm) with coaxiality ≤0.05 mm. Mounting surfaces are milled to flatness ≤0.1 mm/m.

Key Component Manufacturing

Eccentric Shaft: 40Cr steel is forged (forging ratio ≥3), quenched (860°C), and tempered (580°C) to 28–32 HRC. Precision machining ensures eccentricity tolerance ±0.05 mm, with MT inspection to detect surface cracks.

Moving/Fixed Jaws: Cast or welded, then stress-relieved. Mounting surfaces are milled to flatness ≤0.15 mm/m.

Jaw Plates: ZGMn13 is water-quenched (1050°C for 2 hours) to form ductile austenite (impact energy ≥150 J). Tooth profiles are cast using lost-foam technology.

Assembly & Commissioning

Assembly: Bearing blocks are fixed to the frame, followed by bearings, eccentric shaft, moving jaw, toggle plate, and pulley. Bolts are torqued to specifications (e.g., M30 bolts: 450–500 N·m).

No-Load Testing: 2-hour runtime checks bearing temperature (≤70°C), vibration (≤0.1 mm/s), and noise (≤85 dB). V-belt tension is adjusted (deflection 1–2% of span).

Load Testing: 4-hour limestone crushing verifies throughput (≥95% of design capacity), particle size compliance (≥95%), and safety device functionality (toggle plate fractures under simulated overload).

Painting

To ensure reliability (design life ≥10 years, excluding wear parts), quality control spans the entire production cycle:

Raw Material & Blank Inspection

Machining Accuracy

Assembly Quality

Performance Validation

Throughput: ≥95% of design capacity (e.g., PE600×900: ≥104.5 t/h).

Wear Resistance: Jaw plates show ≤5 mm wear after crushing 1000 tons of limestone.

PE series jaw crushers are critical for primary crushing in:

Mining

Reduces blasted ore (500–1500 mm) to 100–300 mm for secondary crushing (e.g., cone crushers). Used in iron ore, copper ore, and limestone mines (e.g., PE900×1200 in 500–800 t/h limestone lines).

Construction Aggregates

Construction Waste Recycling

Metallurgy & Chemicals

Usage Notes:

Feed uniformly via vibrating feeders; maximum feed size ≤85% of the inlet (e.g., PE1200×1500: ≤1020 mm).

Inspect jaw plates every 5000–8000 tons (replace when worn); grease bearings every 2000 hours (lithium-based grease, 1/2–2/3 of bearing cavity).

PE series jaw crushers, with their robust design and versatility, remain indispensable in primary crushing, with model selection based on material hardness, capacity, and site conditions

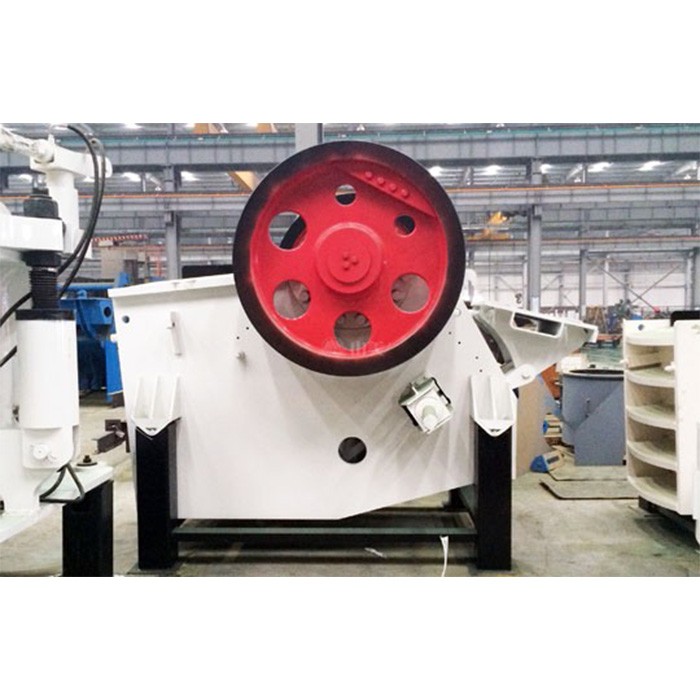

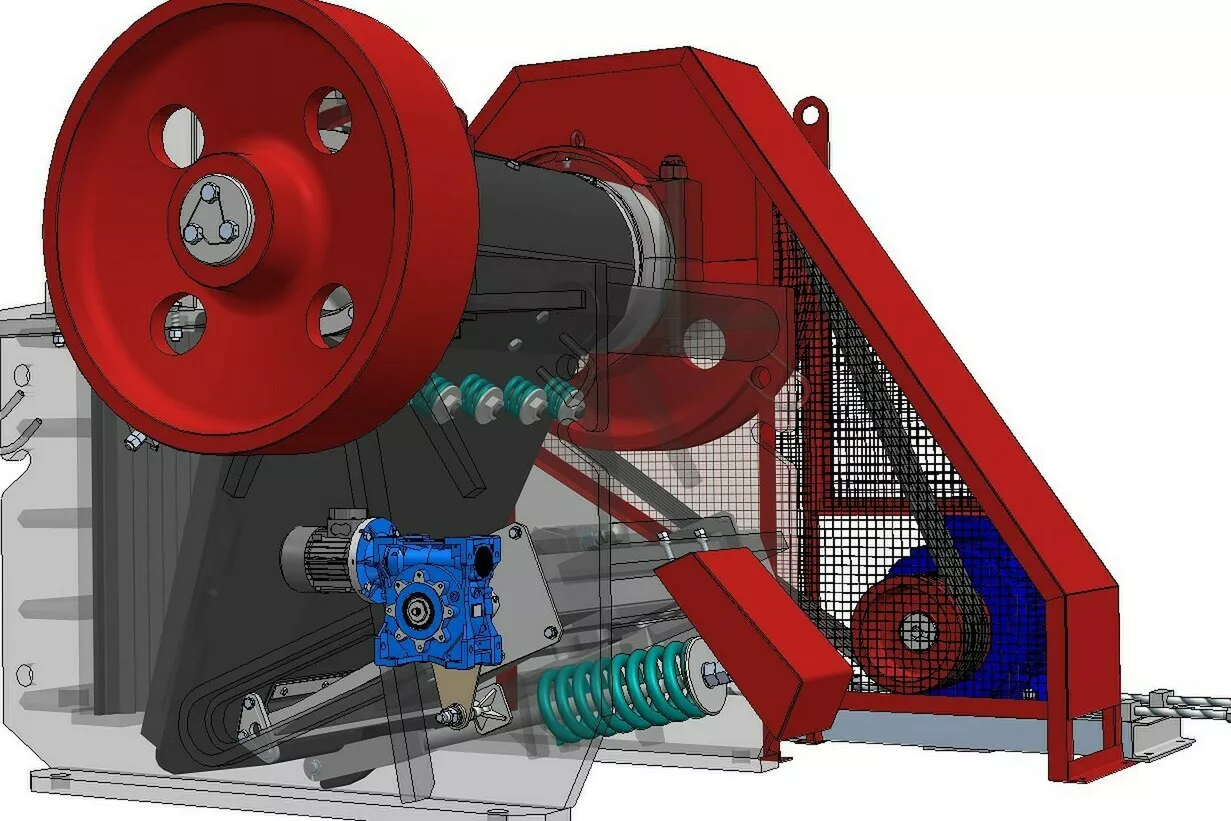

1. The introduction of the single toggle jaw crusher

Shilong single toggle jaw crusher is mainly used for the medium-size crushing of various ores and bulk materials. The advantage is large crushing ratio, uniform product size, simple structure, reliable performance, simple maintenance and low operating costs. It is widely used in the field of mining, smelting, building materials, highway, railway, water conservancy and chemical industries. Used for crushing materials whose compressive strength within 320MPa.

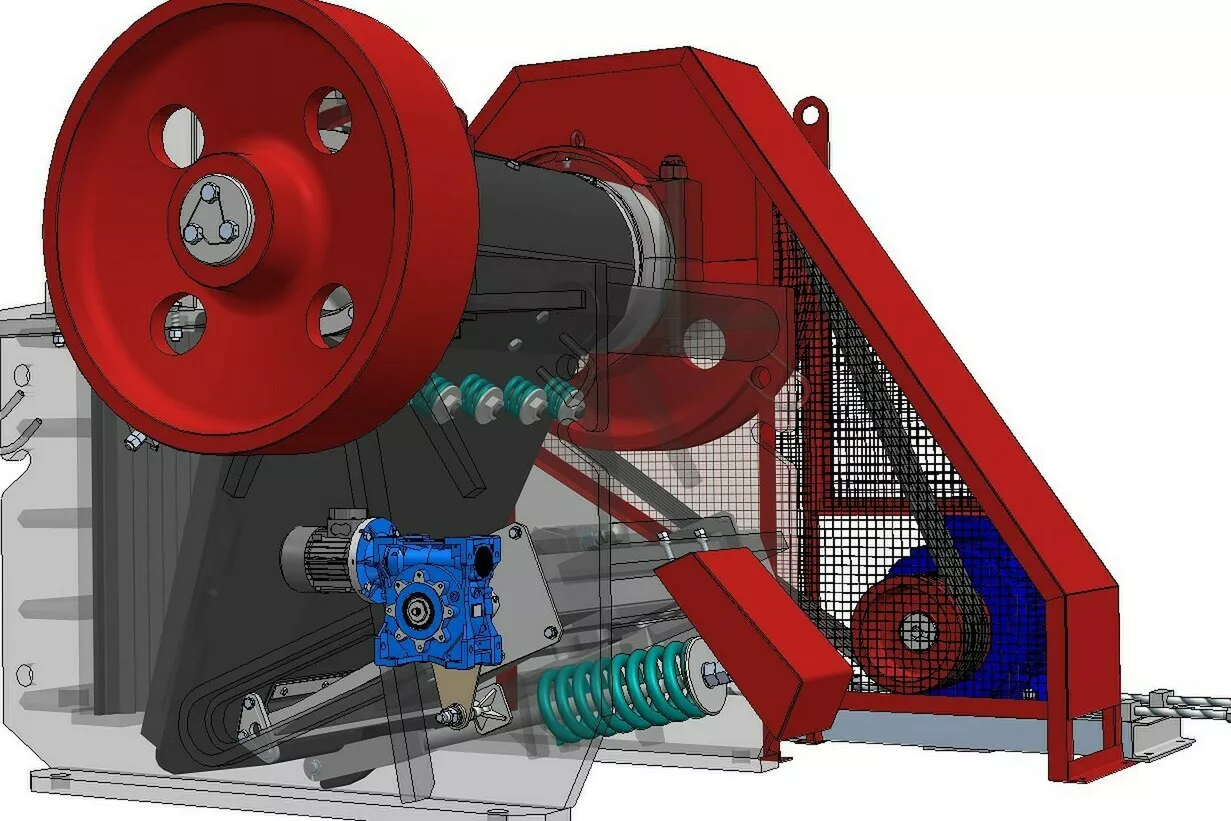

2. Components of single toggle jaw crusher

The main components of the single toggle jaw crusher are frame, jaw plate, side guards, transmission parts, the adjustment device, flywheel and the lubrication device. Each of the components plays an important role in the structure of the jaw crusher.

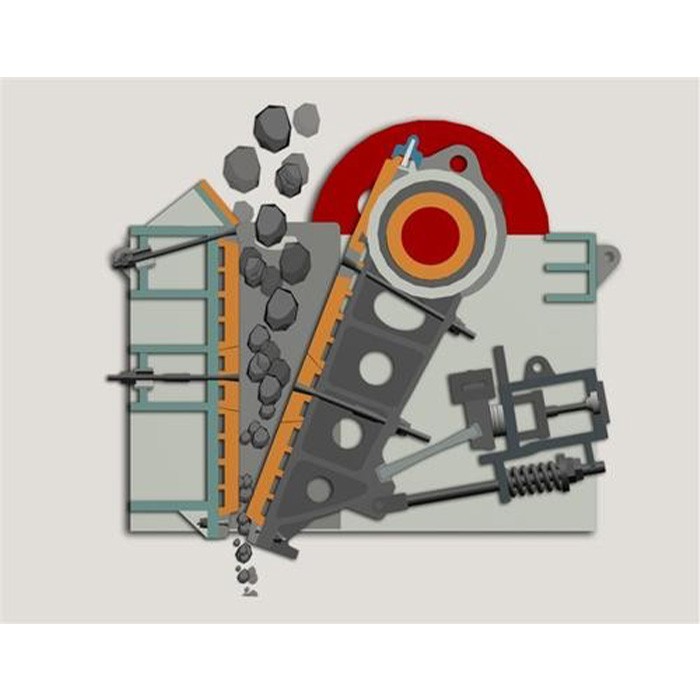

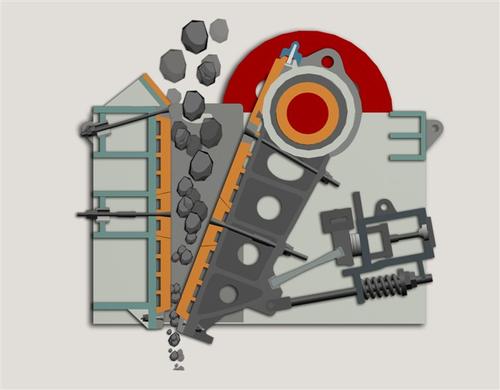

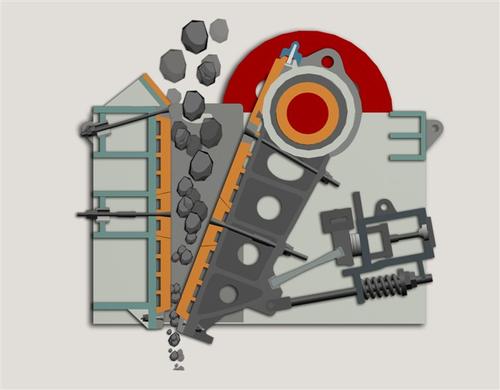

3. Working principle of the single toggle jaw crusher

The motor drives belts,pulleys and movable jaw of the single toggle jaw crusher is suspended on the eccentric shaft. The connecting rod reciprocates up and down once the eccentric shaft rotates. At the same time, the two thrust plates are driven to reciprocate. Thereby pushing the movable jaw to reciprocate left and right to realize crushing. The single toggle jaw crusher adopts the mechanism of the crank double connecting rod. Although the movable jaw is subjected to a great crushing reaction force, the eccentric shaft and connecting rod are not subjected to much force. So it is often used in the industry to crush hard materials. It is called single toggle jaw crusher because of its simple trajectory.

4. Modification of single toggle jaw crusher

The component life of the single pendulum jaw crusher is coordinated with the production characteristics of the system. Our products have high durability, so generally our replacement of crusher will meet the requirements of the situation.

The pur strips of the crusher is repaired by the impact and friction of the material. The wear is relatively fast, and some even bend and break. Generally, new shredded pur strips are used to replace the broken one. Lining repair: The lining is mostly made of high manganese steel, and the wear of the lining can also be repaired by surfacing welding.

At the same time, the gravity of the material makes the material rush from the high-speed rotating hammer to the baffle and the screen rod in the frame. In the lower part of the rotor, there is a sieve plate, the size of the crushed materials smaller than the mesh size is discharged through the sieve plate, and the material with the sieve plate larger than the sieve mesh size remains on the sieve and continues to be hammered and ground until it meets the required discharge size. Finally the material leaves the screen. Let us see how the jaw crusher works. The motor drive belt and pulley of the jaw crusher move up and down through an eccentric shaft. When the moving jaw rises, the angle between the bracket and the moving jaw becomes larger, thereby pushing the moving plate. when the slamming descends, the angle between the bracket and the moving raft becomes smaller, and the moving plate leaves the slab under the action of the pull rod and spring. Therefore, the crushed materials are discharged from the lower port of the crushing chamber of the jaw crusher. As the motor continuously rotates and crushes, the batch materials are crushed and discharged to realize the mass production.

Making simple machines intelligent such as jaw crushers by technology has great significance for improving product technical content ,quality and market competitiveness.

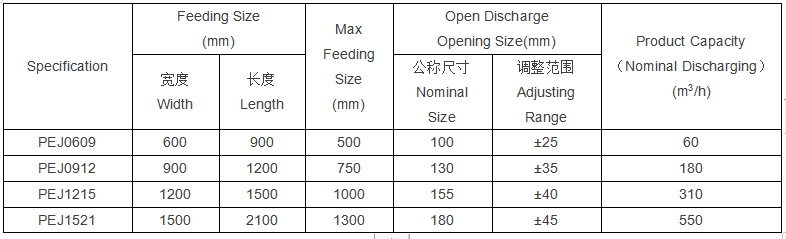

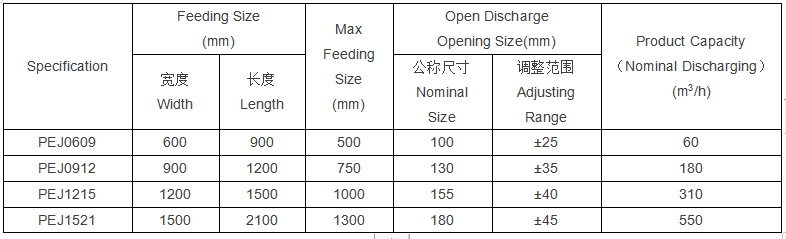

5. PEJ Jaw Crusher Parameter Table