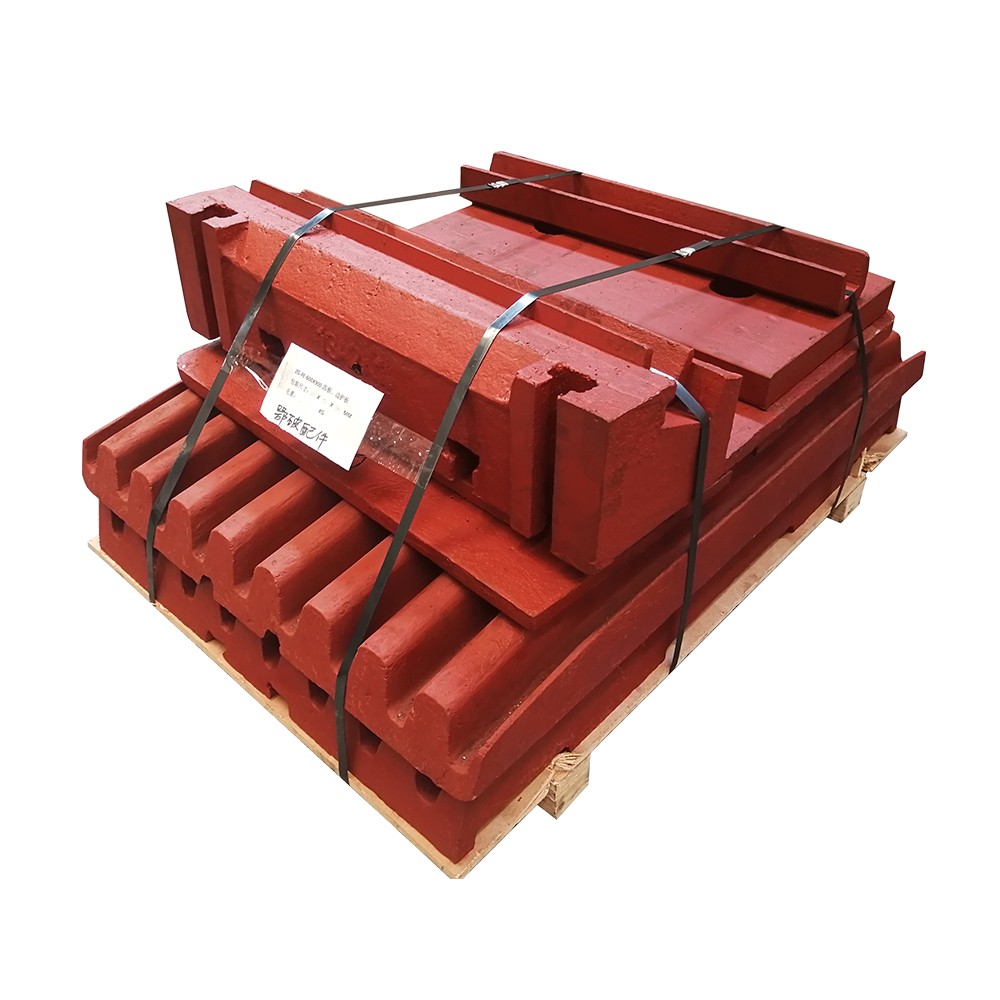

Jaw Crusher Fixed Jaw Plates

The fixed jaw plate is a stationary wear-resistant component in jaw crushers, working with the swing jaw plate to crush materials via extrusion and splitting. Structurally, it features a toothed working surface, bolt holes for mounting, and reinforced edges, typically made of high manganese steel (ZGMn13) for toughness and wear resistance.

Its manufacturing involves sand casting (1400–1450°C pouring) followed by solution annealing to form an austenitic structure, with precision machining to ensure tooth accuracy and mounting fit. Quality control includes chemical composition checks, impact testing, defect detection (UT/MT), and dimensional verification.

With a 4–8 month service life, it ensures efficient, uniform crushing through its design and material properties.

More