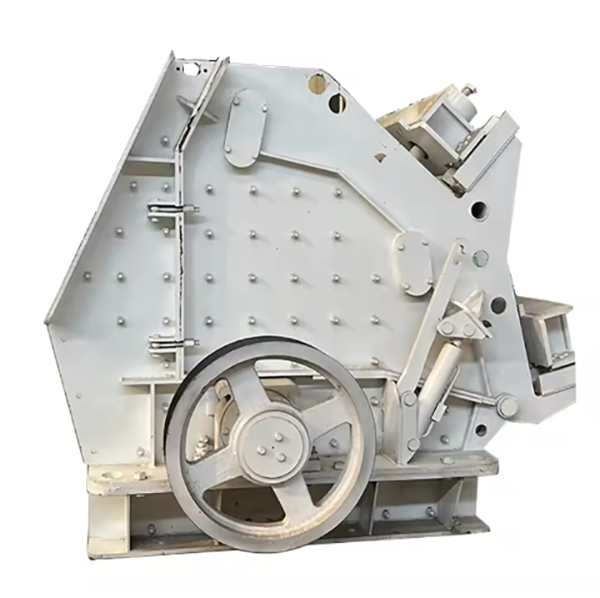

impact Crusher

Impact crusher crushes materials via high-speed impact and rebound, with a rotor (1000–2000 rpm) driving hammers to strike materials, which then rebound to impact plates for secondary crushing. Suitable for medium-hard/brittle materials (≤300 MPa compressive strength) like limestone and ore, it’s widely used in construction, mining, etc., featuring a high crushing ratio (up to 50:1) and good product shape.

Its structure includes: a frame assembly (upper/lower frames), rotor assembly (rotor disk, impact hammers, main shaft, hammer shafts), impact plate assembly (impact plates with adjustment devices), drive system (motor, pulley/belt), and safety/auxiliary devices (guards, dust removal, lubrication).

Key components like impact hammers (high-chromium cast iron) and rotor disks (cast steel) undergo precise casting with heat treatment. Machining processes ensure dimensional accuracy, while quality control involves material testing, NDT (MPT, UT), and performance tests (dynamic balancing, load runs).

Installation includes foundation preparation, frame/rotor assembly, impact plate mounting, drive system connection, and commissioning, ensuring stable operation

More