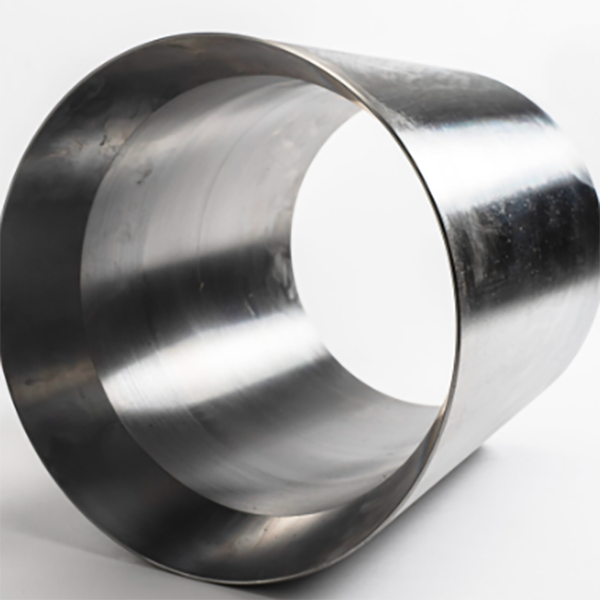

Cone Crusher Main Shaft Sleeve

This paper details the main shaft sleeve of cone crushers, a crucial component positioned between the main shaft and the eccentric assembly. It primarily functions in radial support, friction reduction, load distribution, and lubrication retention. The component consists of the sleeve body, inner bore, outer surface, lubrication channels, flange (in some designs), and wear indicator grooves, each with specific structural features. The casting process for the bronze sleeve body is elaborated, including material selection (phosphor bronze), pattern making, molding, melting, pouring, heat treatment, and inspection. The machining and manufacturing process is also described, covering rough/finish machining, surface treatment, and assembly preparation. Additionally, quality control measures are specified, such as material validation, dimensional accuracy checks, surface quality inspection, functional testing, and wear resistance testing. These processes ensure the main shaft sleeve provides reliable support and friction reduction, enhancing the cone crusher’s efficiency and service life under heavy loads.

More