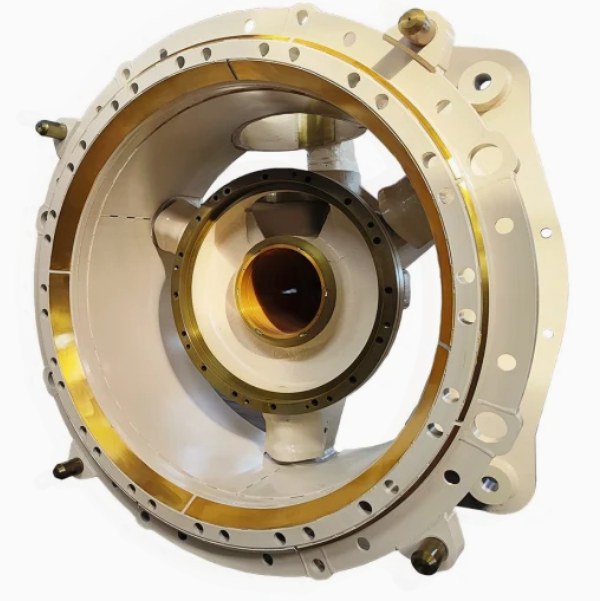

Cone Crusher Frame

The cone crusher frame, as the foundational structural component of the crusher, serves as the "backbone" with core functions including overall structural support (bearing the weight of all components and crushing forces up to thousands of tons), force transmission (distributing loads to the foundation), component positioning (providing precise mounting surfaces), and protective enclosure (housing internal components). It requires high rigidity, strength, and dimensional stability to withstand long-term heavy loads and dynamic impacts.

Structurally, it is a large, heavy-duty casting or welded structure composed of the frame body (high-strength cast steel ZG35CrMo or welded low-alloy steel Q355B with 80–200 mm thick walls), bearing housing, eccentric bushing chamber, mounting flanges (base and upper flanges), reinforcing ribs (30–80 mm thick), lubrication and cooling channels, and inspection and access doors.

For large and complex frames, the casting process involves material selection, pattern making (with 1.5–2.5% shrinkage allowances), molding (using resin-bonded sand), melting and pouring (controlled temperature and flow rate), and cooling and heat treatment (normalization and tempering). The machining and manufacturing process includes rough machining, bearing housing and chamber machining, flange and mounting surface machining, reinforcing rib and external surface machining, and surface treatment.

Quality control processes cover material testing (chemical composition, tensile and impact testing), dimensional inspection (using CMM and laser scanning), non-destructive testing (UT and MPT), mechanical testing (hardness and load testing), and assembly and functional testing. These processes ensure the frame provides stability, reliability, and long service life for the crusher in heavy-duty applications.

More