The counterweight of the Omnicone 1352SX produced by SHILONG, as a specialized component for this model of cone crusher, is a core part ensuring the stable,operation of the equipment. Its design strictly matches the structural parameters of Metso Omnicone 1352SX. In terms of material selection, structural design, and functional adaptability, it fits the high - frequency vibration working conditions of the cone crusher. Here is a detailed introduction:

Basic Materials and Processes

The main body of this counterweight produced by SHILONG is made of high - density HT350 cast iron or QT600 - 3 ductile iron. This kind of material can reach a density of 7.0 - 7.8g/cm³, which can provide sufficient weight suitable for this model. Referring to the standards of counterweights for cone crushers of the same specification, its single weight is likely to be around 450kg, which can meet the balance requirements during the operation of the equipment. During the production process, it is first formed by casting, and then heat treatment is used to strengthen the structural compactness to avoid cracking and deformation under long - tehigh - frequency rotation. A 50 - 100μm thick anti - corrosion coating will be sprayed on the surface to resist dust and moisture erosion in working environments such as mines and quarries, and prolong the service life of the component. Some batches of products will also add a reinforcement structure at the easily worn joints to fit the harsh working conditions when crushing high - hardness materials.

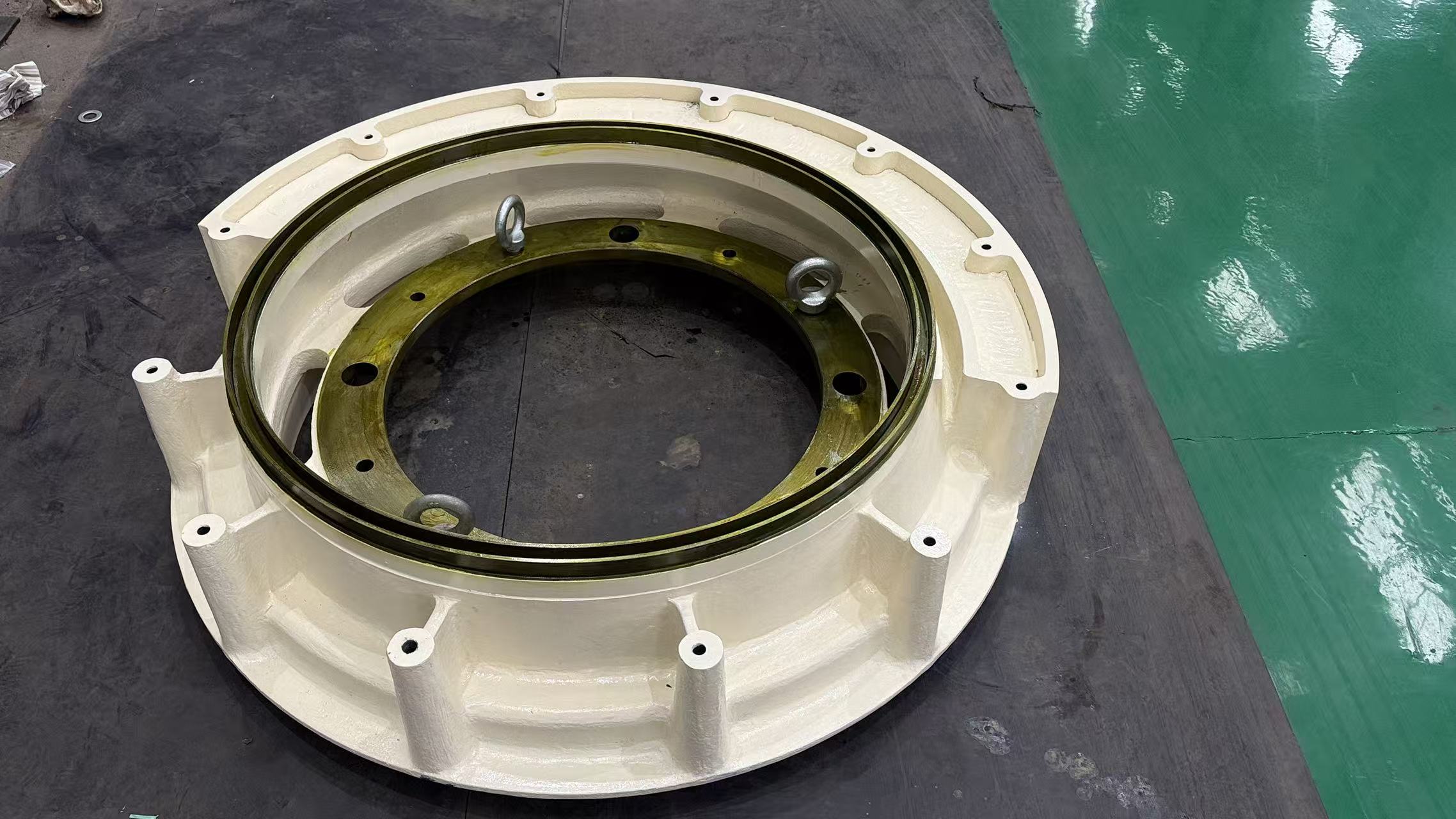

Structural Design Details

This counterweight adopts an annular integral structure that fits the eccentric sleeve of the equipment, and there are also some segmented versions (mostly divided into 2 - 4 segments), which is convenient for on - site installation and later maintenance. There are evenly distributed 8 - 24 high - strength bolt holes of grade 8.8 or above on the circumference of the counterweight, which are used for stable fixing on the eccentric wheel assembly to resist the huge centrifugal force generated during the operation of the equipment. At the same time, it is equipped with cylindrical positioning pins, which can be accurately embedded into the corresponding holes of the eccentric sleeve during installation to ensure the coaxial rotation of the counterweight and the eccentric wheel and avoid angular deviation affecting the balance effect. In addition, an installation position for adjustable balance plates is reserved on the outer ring of the counterweight. Small counterweight blocks (100 - 500g) can be added or reduced to fine - tune the weight distribution to ensure that the equipment reaches the best dynamic balance state. A radial reinforcing rib with a thickness of 10 - 30mm is also designed inside to further improve the structural rigidity and prevent deformation caused by centrifugal stress.

Core Functional Roles

The core function of this counterweight is to balance the centrifugal force when the Omnicone 1352SX is working. When the crusher is running, the eccentric wheel rotates at a high speed and generates a strong eccentric force. At this time, the counterweight will rotate synchronously to form a reverse torque, which greatly offsets this eccentric force, reduces the vibration of the equipment frame, main shaft and bearings, and avoids loosening or premature wear of these core components due to long - term strong vibration. When dealing with materials with uneven hardness such as granite and limestone, the inertia of the counterweight can also help stabilize the pressure in the crushing chamber, avoid sudden changes in the crushing force caused by fluctuations in the particle size of the material, and ensure the uniformity of the discharge particle size. In addition, it can also indirectly reduce the operating noise of the equipment and reduce the probability of material blockage in the chamber caused by vibration, providing a guarantee for the continuous operation of the equipment.

Installation and Maintenance Points

During installation, positioning pins need to be used to complete the accurate alignment of the counterweight and the eccentric sleeve, and then high - strength bolts are used for fastening. It is recommended to apply thread locking adhesive at the bolt connection for anti - loosening treatment to prevent loosening during the operation of the equipment. After putting into use, it is necessary to regularly check the fixed state of the counterweight and the wear of the coating. If loose bolts are found, they should be tightened in time. If the coating is damaged, anti - corrosion materials need to be reapplied. When the equipment has abnormal vibration, the balance plate on the outer ring can be used for fine - tuning, or the vibration sensor detection data can be used to correct the balance accuracy of the counterweight. If the counterweight is deformed, cracked and other problems due to long - term handling of high - hardness materials, it needs to be replaced in time to avoid affecting the crushing efficiency of the whole machine and the service life of other components.

Adaptability and After - sales Guarantee

This counterweight is a customized component produced by SHILONG for the Omnicone 1352SX model, which can perfectly fit the lubrication system and hydraulic control system of the equipment, and can be replaced with original factory components. As a commonly used and easy - to - maintain component of the crusher, SHILONG not only provides spot supply of this counterweight, but also provides corresponding installation guidance services. At the same time, due to its strong adaptability, its after - sales spare parts can be purchased in coordination with components such as the eccentric sleeve and bearings of this model. If maintenance and replacement are needed later, it can also be quickly obtained through the engineering machinery component channels of SHILONG, ensuring the shortest downtime for equipment maintenance.