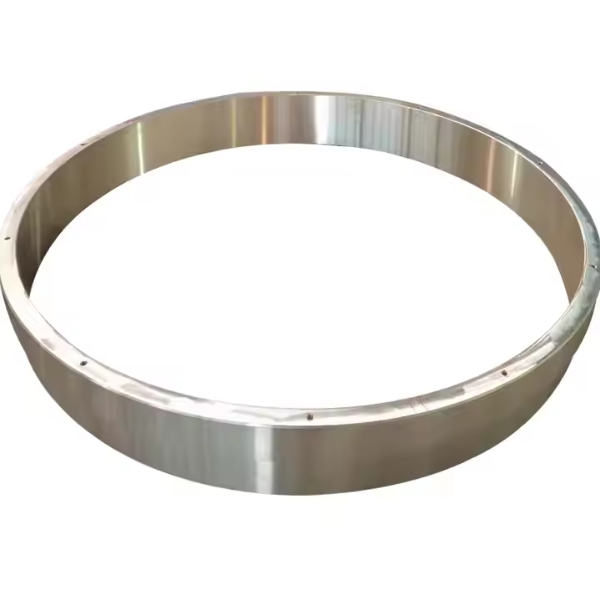

Cone Crusher torch ring

This paper details the cone crusher torch ring, a vital sealing and protective component situated between key assemblies like the adjustment ring and main frame, or moving cone and fixed cone. Its primary functions include high-temperature sealing (withstanding up to 150°C), preventing contamination, thermal insulation, and vibration absorption, requiring heat resistance, oil resistance, and mechanical strength.

The torch ring has a composite structure, consisting of a metal framework (low-carbon or alloy cast steel) with a U/L-shaped cross-section, a sealing liner (high-temperature rubber, graphite composite, or metal-reinforced felt), retention grooves, flange edges, and optional vent holes.

The metal framework is produced via sand casting: material selection (Q235 or ZG230–450), pattern making with shrinkage allowances, green sand molding, melting and pouring (1450–1480°C), cooling and shakeout, and annealing for stress relief. The machining and manufacturing process involves framework machining, sealing liner preparation, liner bonding with heat-resistant adhesive, finishing, and optional surface treatment.

Quality control includes material testing (chemical composition, tensile strength, hardness), dimensional checks (CMM for accuracy), bond strength testing, seal performance evaluations (pressure and heat cycling), and visual/functional inspections. These ensure the torch ring provides reliable sealing in high-temperature, high-vibration conditions, safeguarding internal components and ensuring efficient crusher operation.

More