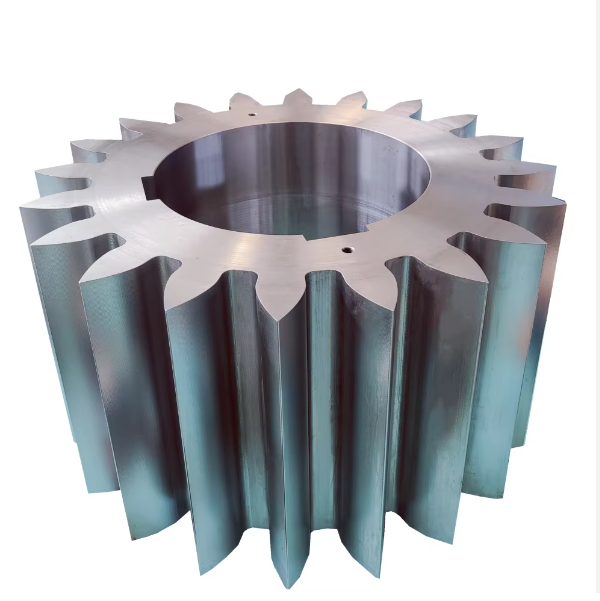

Ball Mill Pinion Gear

This article details the ball mill pinion, a core transmission component that meshes with the bull gear to drive the cylinder, requiring high strength, precision, toughness, and wear resistance, with 20CrMnTi as a common material. It outlines its manufacturing process for 20CrMnTi pinions, including blank forging, rough/semi-finishing (turning, hobbing), carburizing heat treatment, precision machining (tooth grinding, datum grinding), and assembly. Additionally, it specifies comprehensive inspection procedures covering raw materials (composition, forging quality), heat treatment (hardness, carburized layer), tooth accuracy (pitch deviation, runout), and final tests (surface quality, meshing performance, dynamic balance). These ensure the pinion meets transmission efficiency (≥95%) and service life (2-3 years) requirements, supporting stable ball mill operation.

More