Cone Crusher Lubrication System

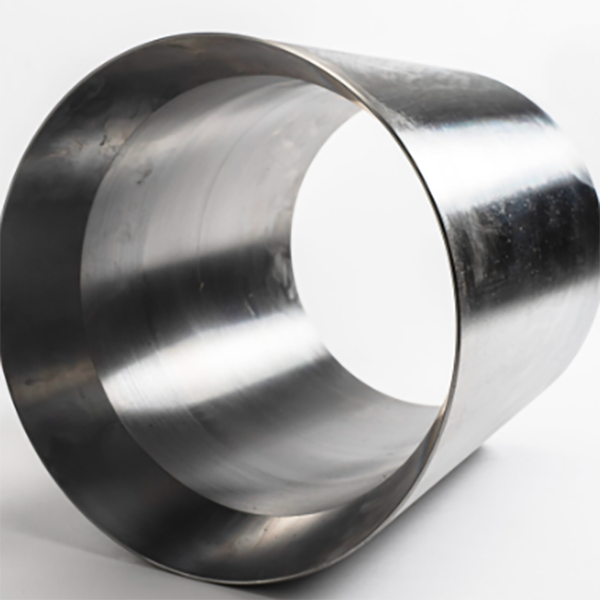

This paper elaborates on the lubrication system of cone crushers, a crucial auxiliary component that reduces friction, dissipates heat, and prevents wear of moving parts by supplying lubricants. It details its composition, including oil tank, oil pump, filtering system, cooling device, distribution manifold, pressure relief valve, and monitoring devices, along with their structural features. The casting process for key cast components (oil tank and pump housing) is outlined, covering material selection, pattern making, molding, melting, heat treatment, and inspection. It also describes machining and manufacturing processes for components like the oil tank, pump housing, filters, and valves, as well as assembly steps. Additionally, quality control measures are specified, including material validation, dimensional checks, performance testing (circulation, pressure, cooling efficiency), safety and reliability verification, and cleanliness verification. These processes ensure the lubrication system reliably protects cone crusher components, minimizing downtime and extending equipment life.

More