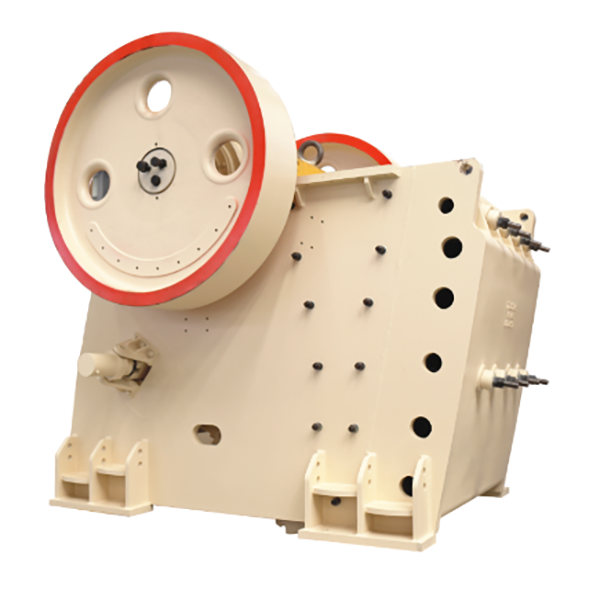

European style Jaw Crusher

European-style jaw crushers (ESJC), adhering to EU standards, feature modular designs, intelligent systems, and advanced environmental performance, tailored for high-end crushing needs. Comprising modular frames, efficient crushing mechanisms (with ceramic-composite jaws), smart transmissions, and hydraulic protection, they offer 10–15% energy savings, ≤80 dB noise, and dust emissions ≤10 mg/m³.

Manufacturing involves precision welding, 42CrMoV eccentric shafts, and digital twin debugging, with rigorous testing (100-hour full-load runs) and certifications (CE, ISO 14001). Quality control ensures -40℃ operability, 0.01 mm precision, and 100,000-hour bearing life.

Widely used in premium aggregate production, metal mining, recycling, and infrastructure, ESJC delivers superior particle shape (flakiness ≤10%), predictive maintenance, and extreme condition adaptability, making it a top choice for high-standard projects globally.

More