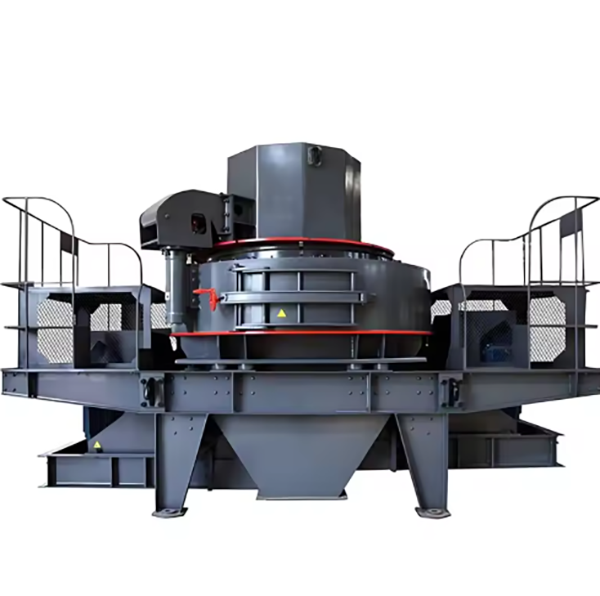

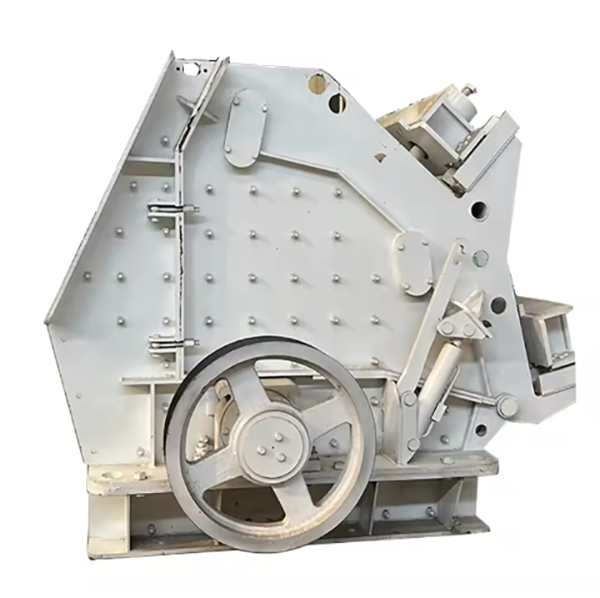

Product Performance

The CS series cone crusher is the company's flagship product in the fine crushing field, fully demonstrating the cutting-edge technology of high-performance spring cone crushers. Based on the principle of layered crushing, and adhering to the core concept of "multi-stage crushing and micro-grinding," this series of equipment achieves superior performance in terms of high capacity, low energy consumption, and uniform product particle size through three major technological advantages: high-frequency vibration, optimized crushing chamber design, and precise stroke matching. This series of products primarily serves the mining, construction aggregate, and metallurgical industries, efficiently processing hard materials such as ores and rocks to meet the needs of continuous and stable production.

product mix

In structural design and manufacturing, the CS series cone crusher adopts an integrated layout solution that seamlessly combines high-strength cast steel frames with wear-resistant alloy crushing components. Both primary transmission parts and crushing assemblies are fabricated from premium alloy materials, ensuring long-term stable operation through precision machining and meticulous assembly processes—even under heavy loads. The mature drive system paired with flexible power options enables the equipment to adapt to diverse material properties and production conditions. By comprehensively considering operational safety, maintenance convenience, and service life, this series delivers highly reliable crushing solutions for customers.

Product Structure

In terms of structural design and manufacturing, the CS series cone crusher adopts an integrated layout, perfectly combining a high-strength cast steel frame with wear-resistant alloy crushing components. The main transmission components and crushing assemblies are all made of high-quality alloy materials, and precision machining and assembly processes ensure long-term stable operation, maintaining stable performance even under heavy loads. A mature drive system combined with flexible power selection options allows the equipment to adapt to different material characteristics and production conditions. By comprehensively considering operational safety, ease of maintenance, and service life, this series provides customers with a highly reliable crushing solution.

Product Parameter

Specification parameters | CS430 | CS440 | CS460 | CS660 |

Rated tonnage (standard) | 77-172 | 99-298 | 291-510 | 314-908 |

Maximum feed particle size (mm/inch) | 223-267 | 400 | 335-500 | 556-622 |

Motor power-kW (hp) | 90 | 132 | 220(295) | 315 |

Close sidebar settings (CSS) Range-mm (inches) | 15-35 | 16-54 | 25-57 | 29-83 |

eccentric stroke Range-mm (inches) | 16-25 | 16-30 | 20-36 | 20-40 |

lining | A,B | A,B | A,B,S | A,B |

Concave surface (outer lining) | EC,C | EC,C,MC | EC,C,MC | EC,C |

Weight (kg/pound) | 7,200(15,873) | 13,000(28,660) | 21,637(47,700) | 40,255(88,747) |

Automation features | select | select | select | select |

lubrication tank | standard | standard | standard | standard |

off-line lubrication filter unit | select | select | select | select |

Application Scenarios

The CS series cone crusher has a wide range of applications. It can efficiently process various types of stone in sand and gravel plants to produce aggregates with reasonable gradations. In mining operations such as iron ore and copper ore, it effectively completes medium and fine crushing. It is also suitable for coal mine crushing, concrete mixing plants, dry mortar plants, as well as power plant desulfurization and quartz sand production processes. This equipment has excellent crushing capabilities for various materials such as pebbles, granite, basalt, iron ore, limestone, and quartz. With its outstanding adaptability and versatility, it has become an ideal crushing equipment choice for many industrial sectors.

FAQ

1. Is this equipment truly suitable for my operating conditions and materials?

The CS series can be selected based on material hardness, feed particle size, and capacity requirements, suitable for various medium and fine crushing conditions.

2. Is the product quality and main components reliable?

Key components are made of high-strength alloy materials, precision-machined, and undergo multiple tests to ensure stable operation and long service life.

3. Does the company have actual manufacturing and delivery capabilities?

We have a mature production system and project experience, enabling stable production and on-time delivery of complete equipment.

4. Is the pre-sale technical support professional and responsive?

We provide rapid response selection advice and technical solutions to assist customers in making the right decisions.

5. Are the after-sales service and spare parts support satisfactory?

We have a comprehensive after-sales service system and a continuous supply of spare parts to ensure long-term equipment operation.

About Us

Shenyang Shilong Machinery Manufacturing Co., Ltd., established in 2000, is an enterprise specializing in the production of mining equipment and core components. Our products cover various types of cone crushers and crushing and screening systems, widely used in mining, cement, power, and petroleum industries. With continuously improving product quality and solid manufacturing processes, Shilong Machinery's products have been sold to many countries and regions worldwide, winning the widespread trust of our customers.

certificate of honor