As core components ensuring the stable operation of SHILONG HPL series cone crushers, the counterweight and eccentric sleeve undergo strict quality control throughout the entire process from raw material selection, precision machining to finished product inspection, integrating industry-advanced technologies and customized control measures. The specific processes are as follows:

1. Counterweight

Structural Design for Deviation Reduction: Adopts a regular split-type structure with cylindrical outer ring and lead pouring grooves reserved within 180 degrees. The inner and outer cylindrical axes of the pouring grooves are coincident, significantly lowering casting and machining difficulty. Meanwhile, the middle fixing plate is bolted to the eccentric sleeve to avoid assembly deviations affecting the center of gravity.

Strict Casting and Lead Pouring Control: High-strength alloy steel is selected as the base material. During casting, strict pouring processes are followed to prevent defects such as porosity and sand holes. In the lead pouring stage, the purity of lead liquid and pouring speed are precisely controlled. After cooling, the compactness of lead pouring is inspected to ensure uniform counterweight density and optimal centrifugal balance performance.

Precision Center of Gravity Detection: Finished products are tested with professional center-of-gravity detectors to verify alignment with the design reference line. Dynamic balance tests are conducted to simulate the counterweight's operation under working speeds of the crusher. Deviations are corrected by fine-tuning the lead pouring amount, reducing vibration and noise during equipment operation.

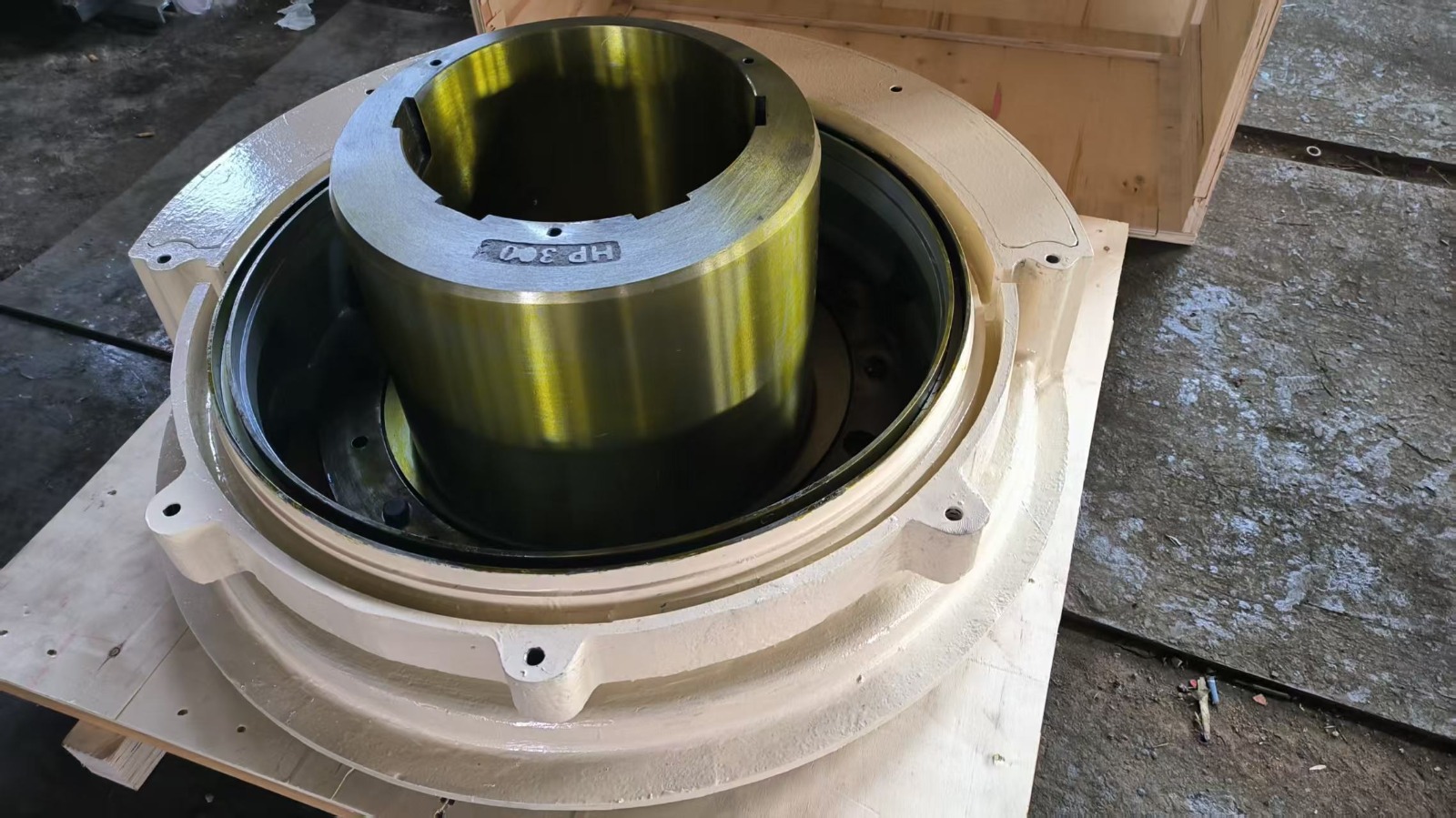

2. Eccentric Sleeve

Custom Fixtures for Machining Precision: Special fixture mandrels and pressure plates are used for combined machining. The taper of the small and large circular platforms of the fixture mandrel strictly matches the taper of the eccentric sleeve's inner hole, and the included angle of the fixture axis is consistent with that of the inner and outer surfaces of the eccentric sleeve. During machining, the inner cone surface is finish-turned first, then the outer circle is processed with the fixture's center pin hole as the reference, ensuring the inclination angle of the inner and outer axes meets tolerance requirements with a gap controlled within 0.05mm.

CNC Precision Machining for Efficiency and Quality: Core machining processes are performed on CNC boring machines to precisely process eccentric inclined holes, avoiding precision deviations caused by tool bar vibration in traditional machining. Balance holes are reserved on the thicker side of the wall. After machining, milling and grinding processes are used to refine the surface, ensuring a smooth outer surface free of pitting and removing residual copper particles and other impurities.

Multi-Dimensional Finished Product Inspection: After machining, the eccentric distance tolerance is inspected to ensure it is within 0.02mm; the interference fit precision with the copper bushing is tested to prevent loosening during operation. Meanwhile, simulated working condition tests are conducted to monitor the bearing temperature rise of the eccentric sleeve (not exceeding 45℃), combined with bevel gear meshing inspection to ensure the tooth surface contact length is not less than 50%, guaranteeing transmission and operational stability.