In the field of mining machinery, the jaw crusher, as the core equipment for primary crushing, its performance directly determines the efficiency and stability of the entire production line. The SHILONG C125 jaw crusher has become the preferred equipment for primary crushing operations in industries such as mining, building materials, and metallurgy due to its precise design, reliable performance, and wide adaptability. This article will comprehensively analyze the core value of this equipment from the dimensions of core technical parameters, structural design, performance advantages, application scenarios, and operation and maintenance key points.

1. Core Technical Parameters: Laying the Foundation for Efficient Operation

Technical parameters are an intuitive reflection of equipment performance. The parameter design of the SHILONG C125 jaw crusher is accurately matched to the needs of heavy-duty primary crushing, with core indicators as follows: The feed opening size is 950×1250mm, which can easily accept large materials with a maximum particle size of 800mm, suitable for primary crushing of various hard rocks; The discharge opening adjustment range is 154-250mm, which can be flexibly adjusted according to subsequent production needs to realize the flexible switching from primary crushing to secondary crushing; The power system is equipped with a 132-160kW motor (different configuration versions), providing strong power support for the equipment, with an hourly processing capacity of 200-500 tons, which can adapt to sand and gravel production lines with a hourly output of several hundred tons; The total weight of the equipment is 39320Kg, adopting a heavy-duty structural design to ensure stability under long-term heavy-load operating conditions. The coordinated design of these parameters not only ensures the equipment's crushing capacity for large materials but also takes into account the controllability of production efficiency and product particle size.

2. Core Structural Design: Balancing Rigidity and Crushing Efficienc

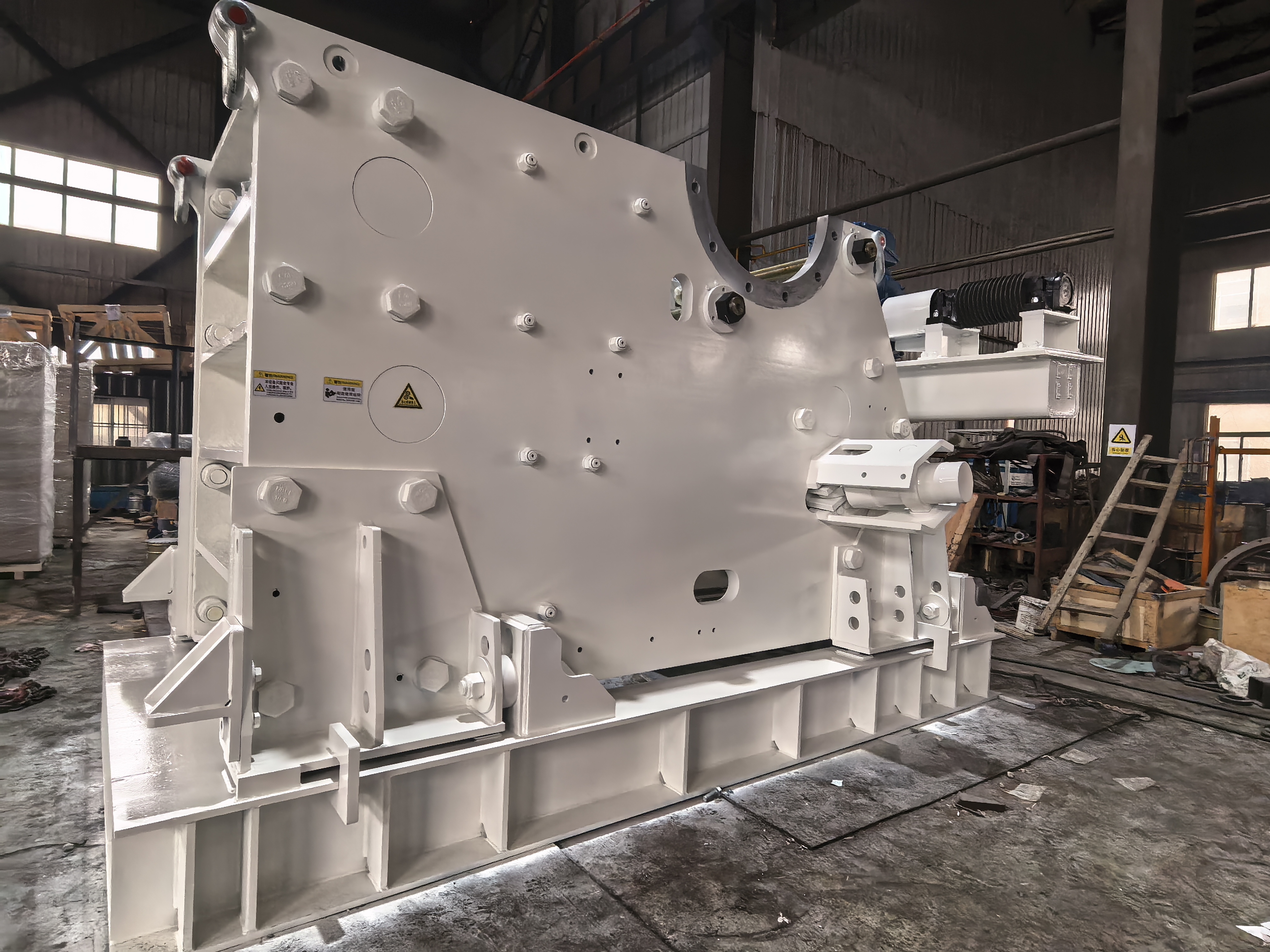

The SHILONG C125 jaw crusher adopts a classic crank-connecting rod extrusion structure and incorporates multiple optimized designs. The core structure and advantages are as follows:

1. Crushing Chamber: Deep V-Shaped Chamber + Three-Section Toothed Jaw Plate

The equipment adopts a deep V-shaped crushing chamber design. Compared with the traditional chamber, it effectively increases the contact length of the jaw plates, improves the residence time and crushing frequency of materials in the chamber, which not only improves the crushing efficiency but also reduces the probability of material blockage. At the same time, it is equipped with three-section toothed jaw plates. Through the multi-directional force design, the materials are subjected to multiple actions such as extrusion and splitting, resulting in more uniform particle size of the crushed products and lower content of needle-like and flaky particles. In addition, the jaw plates adopt an up-down symmetrical design, which can be flipped for use when the bottom end is severely worn, greatly reducing the replacement cost of wearing parts.

2. Transmission and Support System: Heavy-Duty Eccentric Shaft + Large Bearing Design

The transmission system is the core of equipment power transmission. The SHILONG C125 adopts a heavy-duty high eccentricity shaft design. The material is high-strength forged steel and undergoes quenching and tempering treatment, with excellent fatigue resistance and wear resistance; Both ends of the eccentric shaft are equipped with large-size self-aligning roller bearings, which effectively improve the bearing capacity and service life of the bearings, and at the same time adapt to the slight misalignment during the operation of the equipment, reducing component wear. The symmetrical design of the flywheel and pulley can balance the operating load of the equipment, reduce vibration, and ensure stable and efficient transmission process.

3. Adjustment and Protection Mechanism: Wedge-Type Adjustment + Overload Protection

The equipment adopts a wedge-type discharge opening adjustment device. Compared with the traditional bolt adjustment, the operation is simpler and safer. The discharge particle size can be quickly and accurately adjusted in the shutdown state, greatly shortening the adjustment time. In terms of overload protection, through the coordinated design of the toggle plate and the tie rod spring, when non-crushable objects enter the chamber or overload operation occurs, the toggle plate will break first, cutting off the power transmission, and avoiding damage to core components such as the eccentric shaft and frame due to impact; At the same time, the tie rod spring ensures that the moving jaw is closely attached to the toggle plate during the movement process, preventing impact loosening and ensuring stable operation of the equipment.

4. Frame: Integral Heavy-Duty Structure

The frame adopts an integral cast steel or thick plate welded structure, and the welding stress is eliminated through annealing treatment, which greatly improves the structural rigidity and impact resistance. This design can effectively disperse the impact force generated during the operation of the equipment, avoid frame deformation, provide stable support for core components, and ensure the service life of the equipment under long-term heavy-load operating conditions.

3. Core Performance Advantages: Adapting to Complex Operating Conditions

1. Efficient and Stable with Strong Crushing Capacity

Relying on the deep V-shaped chamber, powerful power system and optimized transmission design, the SHILONG C125 can crush various ores, rocks, slags and other materials with compressive strength not higher than 280Mpa, including hard materials such as granite, basalt and limestone. The equipment has a low failure rate and can maintain stable output under continuous operation conditions, providing guarantee for the continuous operation of the production line.

2. Easy Operation and Low Maintenance Cost

The equipment has a simple structure and reasonable layout of key components, which is convenient for daily inspection and maintenance; The wedge-type adjustment mechanism simplifies the discharge particle size adjustment process and reduces the operation difficulty; The high-quality material selection and optimized design of wearing parts such as wear-resistant jaw plates and large-size bearings extend the service life of the components and reduce the replacement frequency and maintenance cost. In addition, the equipment adopts a lightweight design (compared with the traditional PE series), with a smaller volume, which is convenient for transportation and on-site installation and commissioning.

3. Strong Versatility and Adaptability to Diverse Scenarios

The parameter design and performance characteristics of the SHILONG C125 enable it to be widely used in many fields such as mining, sand and gravel aggregate production, construction waste classification and crushing, and metallurgical slag treatment. It can not only be used as an independent primary crushing equipment but also be matched with cone crushers, impact crushers and other equipment to form a complete crushing production line, adapting to diverse production needs with a hourly output of 200-500 tons.

4.Typical Application Scenarios: Empowering Primary Crushing Operations in Multiple Industries

Based on its stable performance and wide adaptability, the SHILONG C125 jaw crusher has been applied in many industries: In the mining industry, it is used for primary crushing of hard rocks such as granite and basalt in open-pit mining to provide qualified materials for subsequent crushing links; In the sand and gravel aggregate industry, as the first crushing equipment of the sand and gravel production line, it processes raw materials such as limestone and river pebbles to produce coarse aggregates that meet building standards; In the metallurgical industry, it is used for primary crushing of materials such as iron ore and steel slag to assist the subsequent processing of metallurgical raw materials; In the construction waste treatment industry, it can crush large construction waste such as concrete blocks and masonry to realize resource recycling and reuse.

5.Operation and Maintenance Key Points: The Key to Extending Equipment Service Life

Scientific operation and maintenance management can effectively improve the equipment service life and operation stability. For the SHILONGC125 jaw crusher, the core operation and maintenance key points are as follows:

Regularly check the wear status of wearing parts such as jaw plates and toggle plates, tighten them in time if loose, and replace them in time if the wear exceeds the standard to ensure crushing efficiency and equipment safety;

Pay attention to the transmission system, regularly check the tension of the V-belts to avoid slipping affecting power transmission, and inject No. 3 synthetic lithium-based grease into the bearings periodically to ensure sufficient lubrication and reduce component wear;

Avoid overload operation and non-crushable objects entering the chamber to prevent failures such as toggle plate breakage and eccentric shaft bending. If material blockage occurs, stop the machine to clear the material before restarting the equipment;

Regularly check the tightness of the anchor bolts of the frame to avoid severe vibration during the operation of the equipment, and ensure that the equipment foundation is stable to reduce the impact of vibration on the surrounding environment and equipment structure.